k-Space is excited to announce that additional information is now available on its website for four of our non-contact solar and glass inspection metrology tools. The glass and solar industries benefit from inline inspection because it greatly improves the quality, yield, and costs for both.

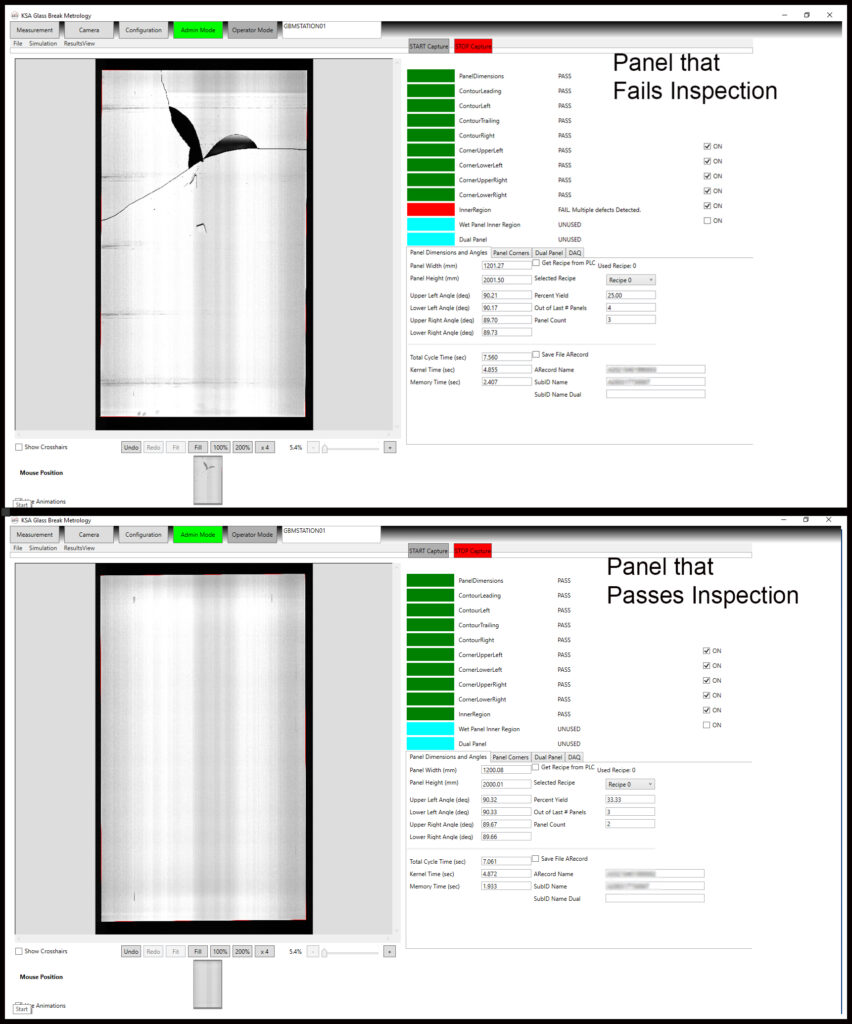

The Glass Breakage Metrology system is for both glass and solar panel defect detection to determine go/no-go conditions for every lite or panel in real-time. The inspection equipment uses a linescan camera, LED lights, and photoeyes. The k-Space software processes the inputs from the machine vision system in real-time to determine if there are any defects. This allows for immediate quality and process decisions. This tool is revolutionizing early glass breakage defect detection in facilities.

The Panel Edge Profile Metrology system measures the edge profile of a glass lite or solar panel using non-contact technology. This system utilizes a 406 nm laser to measure the edge profile in real-time. The k-Space software processes the results and compares them to a standard to determine if the lite or panel passes inspection. The tool can also scan the short-edge and long-edge leading profiles for a full glass profile characterization, including panel width, length, and parallelism.

The Panel Thickness and Flatness Metrology system measures the total glass thickness, flatness (bow, warp, etc.), and total thickness variation using multiple laser sensors. Like all k-Space industrial metrology, we can incorporate alarm systems and integrate data into existing QC systems.

The PhotoResist Thickness Metrology system for solar panels measures the PhotoResist (PR) thickness through thin-film interference fringe analysis from the reflected spectral intensity profile. This is a delta thickness measurement that requires the tool to pre-measure the underlying base film thickness to determine the final thickness of the PR layer. The standard system includes two probes per tool.

The additional information on these tools includes images and system details to provide a better understanding of the systems. k-Space works closely with all customers to determine their specific needs. We can customize any industrial metrology tool and integrate it into existing factory settings including QC systems. To learn more, please email us at requestinfo@k-space.com.