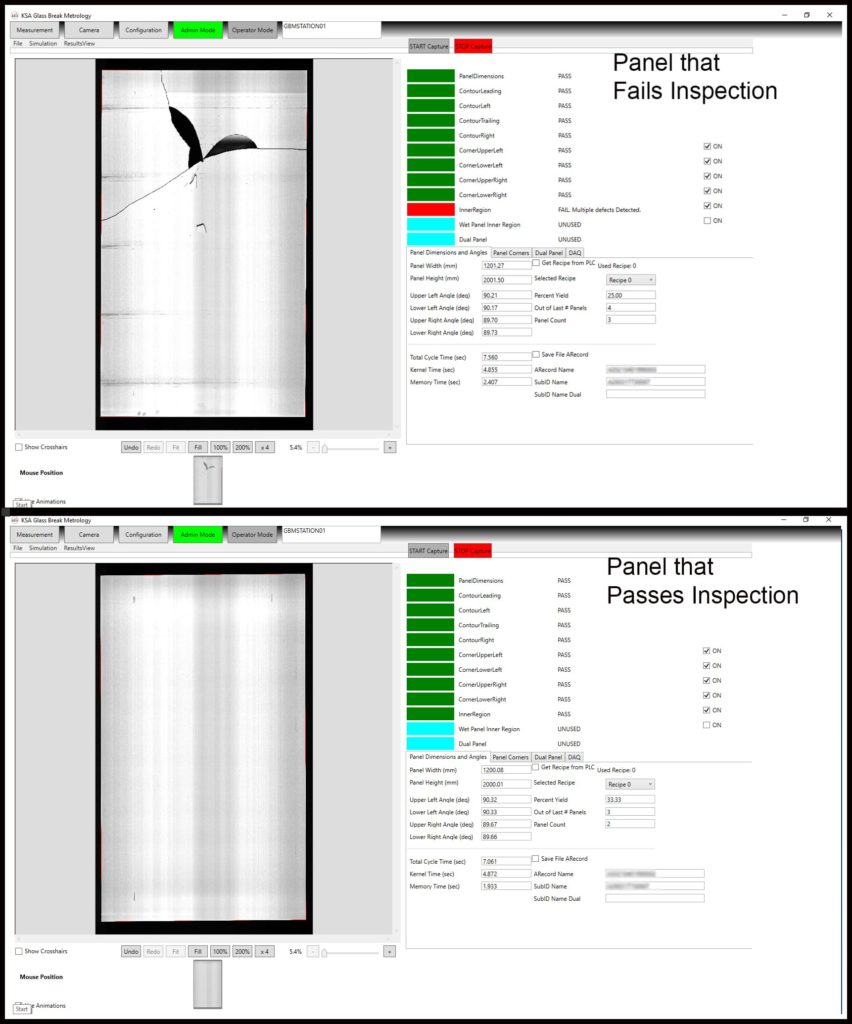

The kSA Glass Breakage and Defect Detection tool is a vision-based metrology system that determines Go/No-Go conditions for every glass lite and panel it inspects during processing. The proprietary system analyzes each panel in real-time for defects and breakage, and optionally can also inspect for color uniformity.

According to k-Space CEO Darryl Barlett, “real-time analysis of glass breakage and defects lets manufacturers quickly scrap defective product and identify upstream manufacturing issues immediately. The result is reduced downtime, lower scrap costs, and fewer returns. And by removing a potential breakage problem early on, that makes for a safer work environment and less damage to downstream equipment.”

Barlett noted that “we work closely with our customers on product development, and several requested that we add the ability to assess panels for color uniformity as well as for potential defects and breakages.”

The kSA Glass Breakage tool can be customized to the manufacturer’s unique product dimensions, standards, manufacturing processes, and production volumes. And it can distinguish between actual defects and minor irregularities.

The kSA Glass Breakage and Defect Detection tool identifies cracks, chips, scratches, digs, pinholes, color uniformity, and other factors. It handles both clear and transparent glass and opaque glass using high-intensity LED light bar modules with safety shielding. Photo eyes detect the leading and trailing edges of the panels and trigger the system to start and stop data collection. Factory integration capabilities enable users to incorporate the tool into their existing systems, including factory alarms, PLC, email alerts, QC (quality control), and more.

To see the kSA Glass Breakage and Defect Detection tool in action, watch this video: