Application Notes : kSA BandiT– Low Temp MBE Measurement

Version: 1.0

- Introduction & Motivation

- Temperature Measurement Challenges

- Blackbody Curve Fitting

- CdTe Buffer: Film Thickness Monitoring

- kSA BandiT Performance Specifications

- Summary

Accurate Temperature Monitoring in Low Temperature MBE Growth

Introduction & Motivation

HgCdTe has proven to be a very efficient detection material for infrared (IR) radiation at wavelengths of tactical and strategic interest for imaging applications. The quality of HgCdTe films grown on CZT (Cadmium Zinc Telluride), GaAs (Gallium Arsenide), and Silicon substrates has improved significantly in recent years, resulting in increased detector performance. However, deposition via Molecular Beam Epitaxy (MBE) is extremely complex and very sensitive to growth temperature. The growth temperature is also typically very low (certain critical layers are < 200°C). These factors make high -quality HgCdTe film growth a real challenge with current temperature monitoring solutions such as pyrometry. k-Space has applied its kSA BandiT system with a new, high sensitivity spectrometer(s) which can now monitor these critical growth parameters in real-time and ultimately provides real-time feedback to the deposition process.

In many cases, the substrate temperature is measured during MBE growth using pyrometry. However, there are many pitfalls to pyrometric temperature measurement. This type of measurement is strictly intensity-based, so is very sensitive to stray light (e.g. hot filament sources), viewport coating, sample emissivity changes, and surface roughness. Emissivity-corrected pyrometry (ECP) can be utilized to compensate for surface emissivity changes, but cannot correct for changes in surface roughness, viewport coating, or stray light.

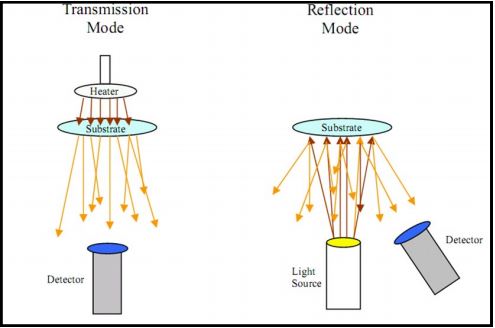

In the case of HgCdTe-based device deposition, not only does the surface emissivity change as different materials are deposited, but most of the materials are deposited at relatively low temperatures. For example, the crucial HgCdTe layer is deposited at less than 200°C. This renders conventional pyrometry and ECP virtually useless for this application as there is not enough radiated signal at these temperatures to properly detect and determine a temperature. Instead, kSA BandiT uses band-edge thermometry (BET), a patented technique which utilizes the inherent band-gap of semiconductors to directly measure substrate temperature. This technique can be used in either a diffuse reflectance or transmission geometry on most MBE systems. In addition, either manual or automated scanning detectors can be used to obtain full 2D temperature uniformity information over large substrates.

Temperature Measurement Challenges During HgCdTe Growth

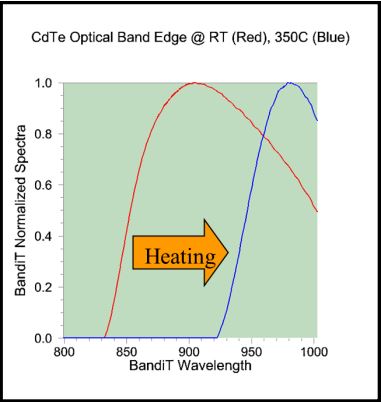

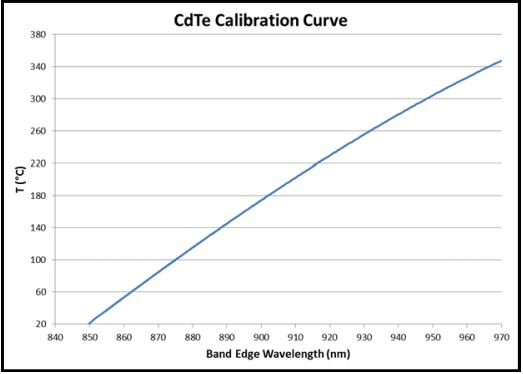

kSA BandiT’s patented, band-edge based temperature measurement technology relies on the shift in band gap energy with change in material temperature. kSA BandiT uses a high-resolution solid-state spectrometer to measure the optical absorption edge of the semiconductor in real time. The measured absorption edge is used to determine the absolute film temperature via a material-specific calibration file, which maps band edge to temperature. The calibration file is generated using calibrated vacuum heating chambers at k-Space to ensure the highest possible temperature accuracy. As a result, direct, accurate, and repeatable measurement of the substrate temperature is guaranteed, and unmatched by any other optical temperature monitoring technique. Temperature resolution during growth is typically ±0.5°C or better. Because BandiT’s technology is insensitive to changing viewport transmission, stray heater radiation, and sample wobble, BandiT is the most accurate and repeatable optical method available for measuring true semiconductor wafer temperature during MBE growth.

The HgCdTe layer growth represents the biggest challenge for temperature measurement and is why BandiT’s band-edge thermometry was chosen. Because of its inherently small band-gap, the HgCdTe will absorb virtually all incident light required for band-edge thermometry once it is sufficiently thick (> 1.2 um in transmission geometry). Due to the low growth temperature, standard or emissivity-corrected pyrometry (ECP) is not applicable either.

BET as a Solution

However, during the initial stages of HgCdTe deposition BET can be utilized with high accuracy, resolution, and repeatability, monitoring either the CdTe, CZT, GaAs, or Si substrate temperature. This is because the band-edge approach is not signal-level dependent, and hence as long as the substrate band-edge can be resolved, a proper temperature will be measured. This can typically be maintained with up to 0.7 um of HgCdTe growth when operating in diffuse reflectance geometry and about 1.2um when operating in transmission.

Using BET to monitor the starting substrate temperature thru this point provides valuable information as the overall substrate/film combination dramatically changes how efficiently it absorbs the substrate heater radiation. Due to this change in heater radiation coupling with increasing HgCdTe layer thickness, the temperature increase during growth is significant, even with constant heater power. Once the HgCdTe layer reaches critical heater IR absorption thickness, this increasing absorption effect is stabilized and a new, lower heater power setting can be found when using BET to maintain the desired growth temperature.

Blackbody Curve Fitting for direct HgCdTe Temperature Calibrations

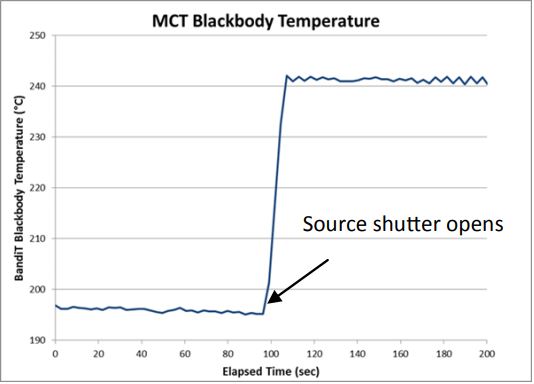

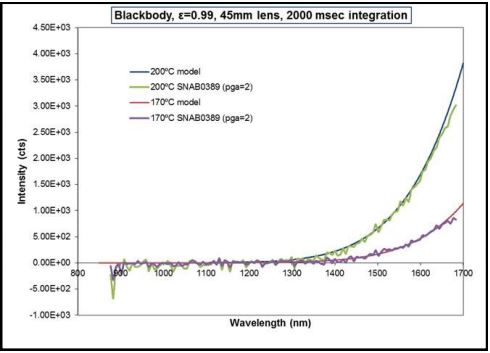

While in general the BET technique performs quite well up to a certain thickness of HgCdTe growth, there are certain circumstances where it can be advantageous to use kSA BandiT’s other monitoring capabilities. To that end, k-Space has previously developed an alternative, blackbody-based temperature measurement which is independent of the band-edge method but uses the same spectrometer and hardware. In this technique, a non-linear least squares method is used to fit a Planck distribution to the above-gap portion of the spectrum in real-time, and the surface temperature is extracted from this fit.

Although this technique is based on the same underlying principles as pyrometry, it has some significant advantages. Pyrometry is based solely on measuring the intensity of radiation emitted by an object in a very narrow wavelength range. Unlike conventional pyrometers, kSA BandiT incorporates a wide-range NIR spectrometer. This allows fitting of a Planck distribution to a blackbody spectrum across a broad range of wavelengths. This makes the technique less sensitive to the various factors which limit the accuracy of conventional pyrometry.

In particular, the temperature extracted from the fit to Planck’s distribution is dependent on the functional form, not just the amplitude. Hence the extracted blackbody temperature is not strongly affected by changes in sample emissivity. Because of the low HgCdTe growth temperature, standard pyrometry techniques are not possible. Therefore BandiT’s self-calibrating blackbody radiation analysis technique is the best available means of temperature measurement or calibration in this regime.

However, despite the fact that blackbody temperatures as low as 170°C can be measured with high resolution and accuracy using a cooled NIR spectrometer, this technique is very challenging in the growth environment: multiple sources of stray blackbody radiation are typically present. If these sources of stray light are controlled, the Blackbody technique can provide a powerful means to better understand substrate temperature after 1.2um of HgCdTe growth, when BET is not viable.

kSA generation calibration files are used to accurately determine temperature via band-edge thermometry

kSA generation calibration files are used to accurately determine temperature via band-edge thermometry

kSA BandiT band-edge spectrum showing HgCdTe films of varying thickness deposited onto CZT substrates. Increased thickness lowers the overall signal level, but does not affect the band-edge position which leads to repeatable temperature measurements up to ~1.2um of film deposited. After 1.2 um of HgCdTe is deposited, kSA Blackbody curve fitting is used.

kSA BandiT band-edge spectrum showing HgCdTe films of varying thickness deposited onto CZT substrates. Increased thickness lowers the overall signal level, but does not affect the band-edge position which leads to repeatable temperature measurements up to ~1.2um of film deposited. After 1.2 um of HgCdTe is deposited, kSA Blackbody curve fitting is used.

kSA BandiT blackbody curve fitting using high sensitivity NIR spectrometer for temperature measurement of HgCdTe below 200 degrees C. Care must be taken to avoid sources of dynamic stray light such as MBE source shutters or other hot filaments.

kSA BandiT blackbody curve fitting using high sensitivity NIR spectrometer for temperature measurement of HgCdTe below 200 degrees C. Care must be taken to avoid sources of dynamic stray light such as MBE source shutters or other hot filaments.

CdTe Buffer: Film Thickness Monitoring

By using the same NIR spectrometer used for BET, the CdTe film thickness can be determined from the wavelengths of the extrema in the below-gap portion of the diffusely reflected NIR spectrum. After ~ 1.5um of deposition, thickness resolution of better than +/- 1nm can typically be achieved. The required dispersion relation of the film material is calculated within the kSA BandiT software via entering the Sellmeir coefficients A0, A1, and A2:

![Rendered by QuickLaTeX.com \[ n^2(\lambda) = {A_0}^{2} + \frac{{A_1}^{2}}{\lambda^2 - {A_2}^{2}} \]](https://k-space.com/wp-content/ql-cache/quicklatex.com-f7c4112f533164d5648fbaabab67b082_l3.png)

Note that the BandiT algorithm assumes that the energy range used is far enough below the band gap that the film is non-absorbing, i.e. the imaginary part of the complex index (a.k.a. the extinction coefficient k) is zero. CdTe buffer layer thickness measurement is performed in real-time alongside BandiT’s temperature measurements.

A CdTe buffer layer deposition is typically performed as a transition to HgCdTe when using Silicon or GaAs substrates. Because the CdTe bandgap is larger than the underlying Si or GaAs substrate, it will effectively be transparent to light that is, in turn, absorbed by the Si/GaAs substrate.

kSA BandiT Performance Specifications: HgCdTe MBE Growth

| Substrate Temperature | ||||

| Substrate | kSA Technology Used | Temperature Range (°C) | Accuracy (°C) | Repeatability (°C) |

| Bare CZT, CdTe, GaAs, InP, Silicon | Band Edge Thermometry | RT-600 | ± 2 | ± 0.5 |

| Substrates with >1um of HgCdTe film applied | Blackbody Curve Fitting | 180-1200 | ± 2 (w/stray light controlled) | ± 1 (w/stray light controlled) |

| Film Thickness | ||||

| Substrate | kSA Technology Used | Thickness Range | Accuracy (nm) | Repeatability (nm) |

| CdTe Buffer Layer on GaAs or Silicon | Spectral Film Thickness Determination | 0.5-10um | ± 1nm (>1.5 um film) | ± 0.5nm (>1.5 um film) |

kSA BandiT for HgCdTe MBE: Summary

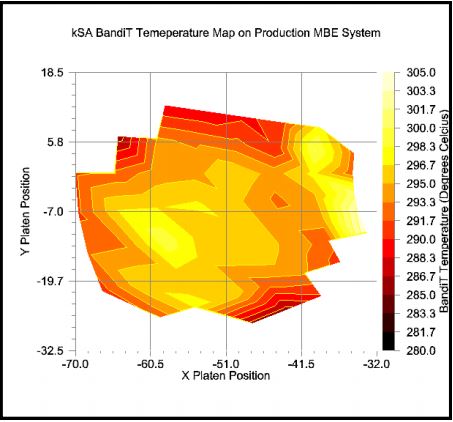

Leveraging over 20 years of in situ monitoring technology and experience, k-Space has successfully developed real-time kSA BandiT product technology for low temperature measurement of HgCdTe material growth during during MBE . The newly developed kSA BandiT in situ metrology tool uses solid state spectrometer technology to measure band-edge temperature (BET) at the sub-200 °C level, with unmatched accuracy and repeatability. This capability enables better control of sample temperature during the initial stages of HgCdTe growth and can even provide a full 2D thermal profile map in the MBE system and ensure proper heater uniformity tuning over larger substrates. The system also measures CdTe buffer layer thickness using the same NIR spectrometer, when working with GaAs and Silicon substrates. In addition, the patented Blackbody temperature technique (also included within the kSA BandiT system) provides an excellent means for monitoring or calibrating HgCdTe material growth temperature below 200°C during the remaining epilayer growth (when stray light is controlled in the MBE chamber). Please contact k-Space at [email protected] or +1 734-426-7977 for more information!