kSA ACE provides atomic flux control with accurate and high-resolution source flux and growth rate monitoring for thin-film deposition.

The kSA Atomic Control for Epitaxy (ACE) metrology tool is a highly sensitive instrument that measures the in situ flux rate of atomic species using the principle of atomic absorption spectroscopy. The kSA ACE system uses conventional hollow cathode lamps (HCLs) to generate the atomic emission for the elements of interest. It also utilizes a high-sensitivity, UV-optimized solid-state spectrometer to monitor the absorption, along with a second spectrometer to monitor signal drift from the HCLs. Because the technique is inherently material specific, the signal does not respond to other species or radiation in the chamber. kSA ACE can measure each material of interest independently with high accuracy, providing precise material-specific flux control in multi-source deposition processes. With its high sensitivity and long-term repeatability under continuous operation, kSA ACE has applications in the fabrication of III-V and II-VI compounds, semiconductor devices, thin-film sensors, solar cells, optical coatings, x-ray optics, flat-panel displays, and more.

The kSA Atomic Control for Epitaxy (ACE) metrology tool is a highly sensitive instrument that measures the in situ flux rate of atomic species using the principle of atomic absorption spectroscopy. The kSA ACE system uses conventional hollow cathode lamps (HCLs) to generate the atomic emission for the elements of interest. It also utilizes a high-sensitivity, UV-optimized solid-state spectrometer to monitor the absorption, along with a second spectrometer to monitor signal drift from the HCLs. Because the technique is inherently material specific, the signal does not respond to other species or radiation in the chamber. kSA ACE can measure each material of interest independently with high accuracy, providing precise material-specific flux control in multi-source deposition processes. With its high sensitivity and long-term repeatability under continuous operation, kSA ACE has applications in the fabrication of III-V and II-VI compounds, semiconductor devices, thin-film sensors, solar cells, optical coatings, x-ray optics, flat-panel displays, and more.

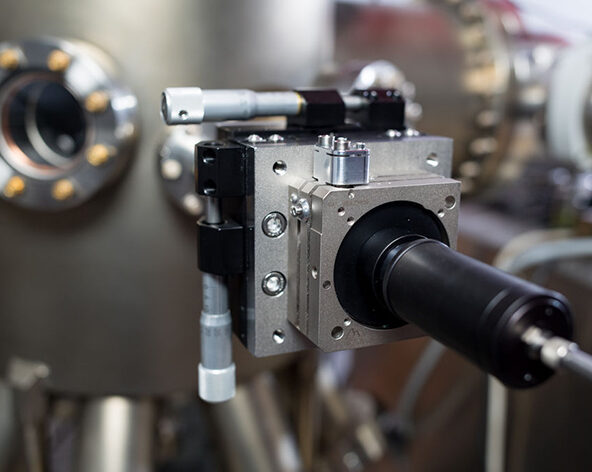

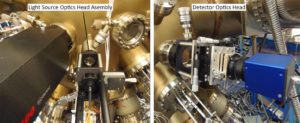

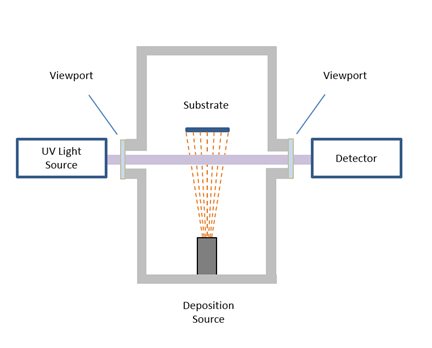

The kSA ACE instrument combines the UV atomic emission lines of up to three hollow cathode lamps (HCLs) into a colinear beam. The beam is split into a reference channel and a signal channel. The system continuously monitors both the reference and the signal channels with high-sensitivity, high-spatial-resolution spectrometers that monitor up to three elements simultaneously. The reference channel provides continuous correction for HCL intensity fluctuation. The signal beam is fiber coupled to lens cells on the process chamber and then passed through the flux of the deposition sources, resulting in attenuation of the atomic lines, specific to the resonant absorption of the atom species. The attenuation is proportional to the atomic density within the volume of the signal channel beam. The system also includes a Xe flash lamp, colinear with the HCL beam path, to correct for viewport coating. The entire optical subsystem, including HCLs, beam collimation optics, and spectrometers, is temperature stabilized, to ensure long-term stability and accuracy.

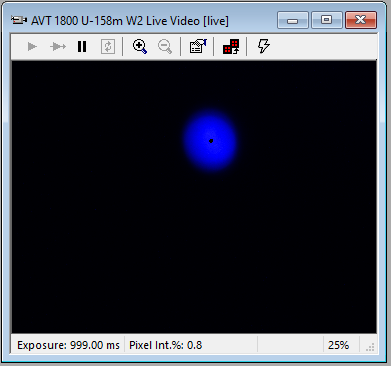

AA Light Spot Real-Time Imaging

Another useful feature of the system is the integrated camera that captures live video of the AA light spot as it looks once it has traversed the deposition path. This real-time imaging of the light spot allows for easy alignment of the tool, tracking of any spot drift, and characterization of the spot profile. Optionally, servo motors can be installed on the detector for real-time centering of the AA spot, minimizing any optical drift of the system.

Another useful feature of the system is the integrated camera that captures live video of the AA light spot as it looks once it has traversed the deposition path. This real-time imaging of the light spot allows for easy alignment of the tool, tracking of any spot drift, and characterization of the spot profile. Optionally, servo motors can be installed on the detector for real-time centering of the AA spot, minimizing any optical drift of the system.

Measurement and Process Control

k-Space designed the kSA ACE using feedback from industry-leading scientists. The system is engineered to operate up to three sources at the same time with exceptional stability. k-Space can design systems to meet your specific needs, with options such as automated alignment drift compensation and motorized auto-alignment correcting light source optics heads. With kSA ACE, you can measure and control:

- Real-time flux transmission/absorption

- Real-time growth rate

- Real-time composition control

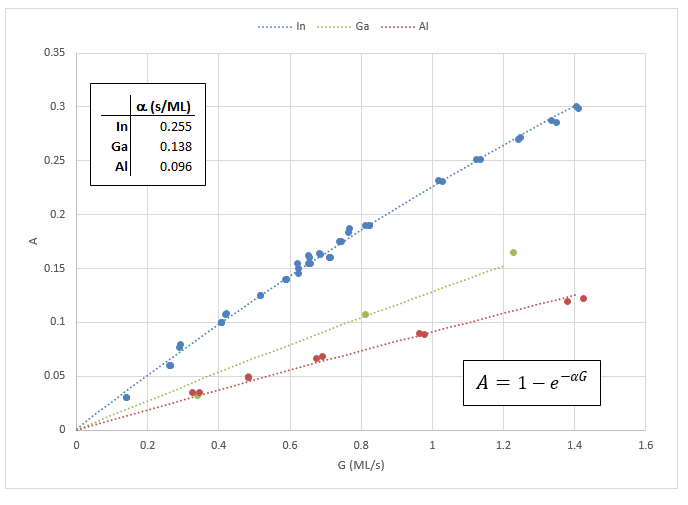

The chart shows the absorption of specific atomic lines for In, Ga, and Al over a range of growth rates, following the Beer-Lambert law. The data was taken with a kSA ACE system on a Gen III MBE reactor equipped with atomic absorption ports.

Processes

The kSA ACE is ideal for many thin-film deposition processes, including:

The kSA ACE is ideal for many thin-film deposition processes, including:

- Molecular Beam Epitaxy (MBE)

- Evaporation: Knudsen (effusion) cells, e-beam source, ion-beam assisted, induction source, resistive heat source

- Sputtering: RF/DC magnetron, ion-beam, reactive

- Pulsed laser deposition

- Plasma etch processes

It provides the high sensitivity and stability needed for accurate and high-resolution flux and growth rate monitoring during these processes.

Material Examples

The sensitivity of the kSA ACE system depends on the material being measured and the absorption path. The system cannot detect molecular species such as molecules from a compound sputtering target, or molecular species such as As2, Se2, etc., from evaporation sources. Some materials are not available in hollow cathode lamps.

The sensitivity of the kSA ACE system depends on the material being measured and the absorption path. The system cannot detect molecular species such as molecules from a compound sputtering target, or molecular species such as As2, Se2, etc., from evaporation sources. Some materials are not available in hollow cathode lamps.

Some examples of materials that kSA ACE can measure (atomic species required): Ag, Al, Au, Ba, Bi, Ca, Cd, Co, Cr, Ca, Cu, Dy, Fe, Ga, Ge, Hf, In, La, Mg, Mn, Mo, Ni, Pb, Si, Sn, Sr, Ta, Ti, W, Y, Zn, and Zr.

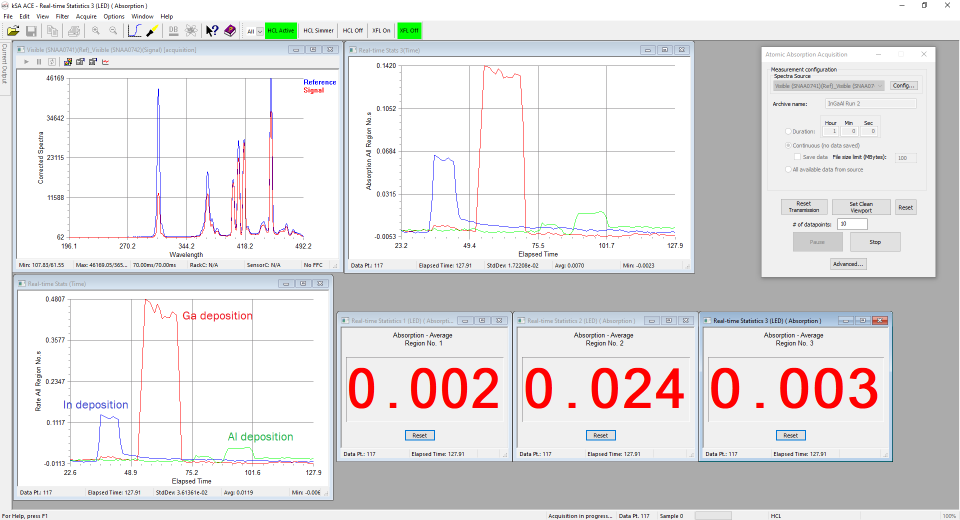

The kSA ACE software is built on the well-known k-Space software platform and offers a user-friendly interface with flexibility and customizability. It provides a variety of screens that enable you to monitor things such as source cell transmission vs time, live absorption spectra, HCL and reference signal levels, and HCL lamp current. All data is conveniently stored to user-selectable data file formats, and digital I/O, analog I/O, and TCP/IP communications are available for chamber control and interfacing.