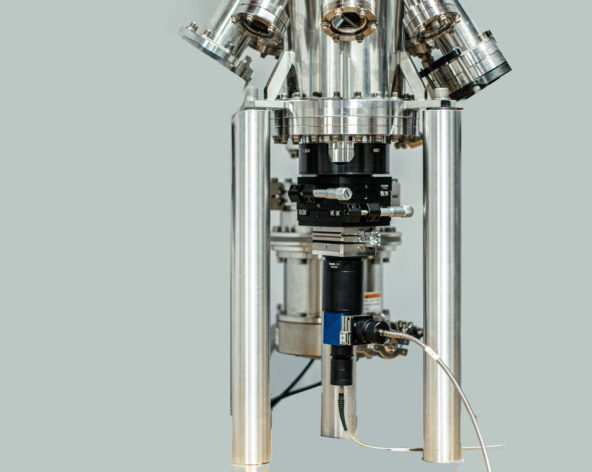

The kSA SpectR is an optically-based real-time wafer and film spectral reflectance monitor used for monitoring thin-film deposition and processing. Let the light give you insight into your process!

The kSA SpectR is a complete metrology solution for measurement of absolute spectral reflectance, growth rate and end point detection. Custom spectral features such as reflectance minima, maxima, inflection points, or baseline scatter level, over a user defined wavelength range of interest, are easily measured. When monitored as a function of time during deposition, the film growth rate can also be determined. The kSA SpectR optics are typically configured in a specular reflection geometry. The wavelength range for the kSA SpectR can be specified by the user, but typical ranges include 380-1100nm and 890-1650nm. The kSA SpectR is typically used to monitor thin-film deposition and processing of VCSELS, DBRs, and other complex device structures. Typical deposition methods include MBE, MOCVD, and sputtering.

The kSA SpectR is a complete metrology solution for measurement of absolute spectral reflectance, growth rate and end point detection. Custom spectral features such as reflectance minima, maxima, inflection points, or baseline scatter level, over a user defined wavelength range of interest, are easily measured. When monitored as a function of time during deposition, the film growth rate can also be determined. The kSA SpectR optics are typically configured in a specular reflection geometry. The wavelength range for the kSA SpectR can be specified by the user, but typical ranges include 380-1100nm and 890-1650nm. The kSA SpectR is typically used to monitor thin-film deposition and processing of VCSELS, DBRs, and other complex device structures. Typical deposition methods include MBE, MOCVD, and sputtering.

Absolute Spectral Reflectance, L*a*b*, and Growth Rate

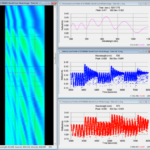

The kSA SpectR optics are set up in a specular reflectance geometry. The unit is calibrated to a known reflectance substrate, e.g. sapphire or Si. Subsequent measurement of the thin-film deposition and process steps yield absolute spectral reflectance measurement, as well as the L*a*b* color parameters. In addition, by monitoring the reflectance at a given wavelength vs time, growth rate can be determined. k-Space utilizes a method developed at Sandia National Laboratory and licensed to k-Space. In this approach, the fitting routine restarts with each new layer, treating the underlying film stack as a “virtual” substrate. The measurements can be performed simultaneously at multiple wavelengths, each of which offers potential advantages. In the example shown, the use of a 532 nm laser allows the fit to converge quickly, enabling the measurement of thinner films. On the other hand, the lower absorption at the 940 nm wavelength enables the measurements to be extended to thicker films. Available wavelengths include, but are not limited to, 375, 405, 532, 660, 940, and 980 nm, utilizing either laser or LED light sources.

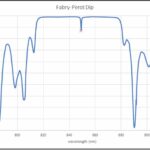

Identification of Custom Spectral Features

Customizable real-time spectral analysis allows the user to configure the software to identify specific features within a certain wavelength range for optimizing process control and feedback. For example, the Fabry-Perot dip (F-P dip), which is a sensitive indicator of the layer thicknesses, can be precisely determined during Distributed Bragg Reflector (DBR) growth.

The kSA SpectR software is a full featured package that controls and monitors the light source, spectrometer(s), and all data I/O.

- The system utilizes signal intensity changes in the wafer and carrier to define measurement locations during rotation (if required). Wide markers are available when averaging is desirable.

- Multi-wafer acquisition is available for full real-time integration and display of all pertinent acquisition parameters, at all marker positions.

- Complete TCP/IP interface for custom, real-time data transfer and program control.

- Ability to write data in real-time to an SQL database

- Complete analog and digital I/O capability.