Every industry has need for measurement. k-Space’s high-tech, non-contact, optical inline metrology is all custom designed, making it the ideal solution for precise dimensional measurements, as well as visual inspection.

If you need accuracy for any dimensional measurement, from sizes not discernable to the human eye to very large, you are in the right place. We have implemented inline metrology systems that measure industrial film thickness as negligible as 50 nm in certain circumstances, all the way up to systems that measure parts several feet in dimension. All of these metrology systems provide extreme accuracy.

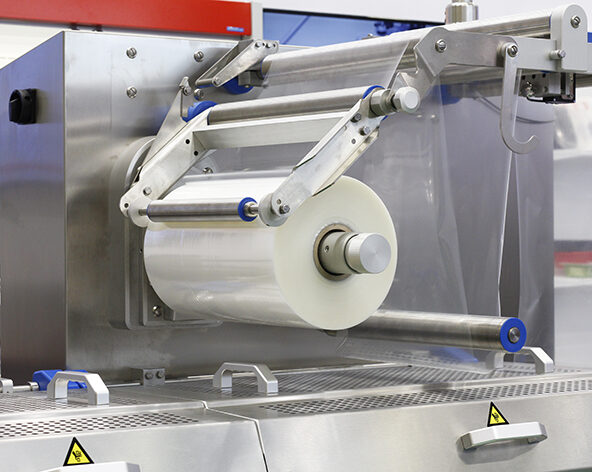

Our industrial metrology has been placed in roll-to-roll, horizontal conveyor, angled conveyor, coating chamber, and other applications. As long as there is visual access, we can help you design a solution that meets your measurement needs.

Read about some of our customers’ experiences with a roll-to-roll film thickness measurement system and a gypsum board building product metrology system in the linked case studies.

It’s more than just a measurement tool. It’s a complete inline metrology system that we can either integrate with your existing quality control infrastructure or that can be a standalone database and analysis system that also provides real-time readouts. Through our vast knowledge base and the skills of our solution-focused software engineers, product engineers, and physicists, we can help you develop a solution that will keep your quality and yield where you want them to be.