In Situ Wafer Temperature and Film Temperature Measurement

Precise wafer temperature measurement and control during film growth is critical to achieving high device yield and performance. Achieving this control necessitates accurate real-time measurement. k-Space offers five in situ thin-film metrology tools that measure wafer temperature and/or film temperature with various methods. kSA BandiT incorporates band edge, blackbody, and pyrometry temperature measurements. kSA BandiT PV and kSA ICE both incorporate the kSA BandiT technology. kSA ICE is a modular design that allows for measurement of more than just wafer temperature. kSA SpectraTemp measures absolute temperature and can be used to calibrate pyrometers. kSA Scanning Pyro is a scanning pyrometer designed for MOCVD systems. See each product below to determine which is best for your wafer and film temperature measurements.

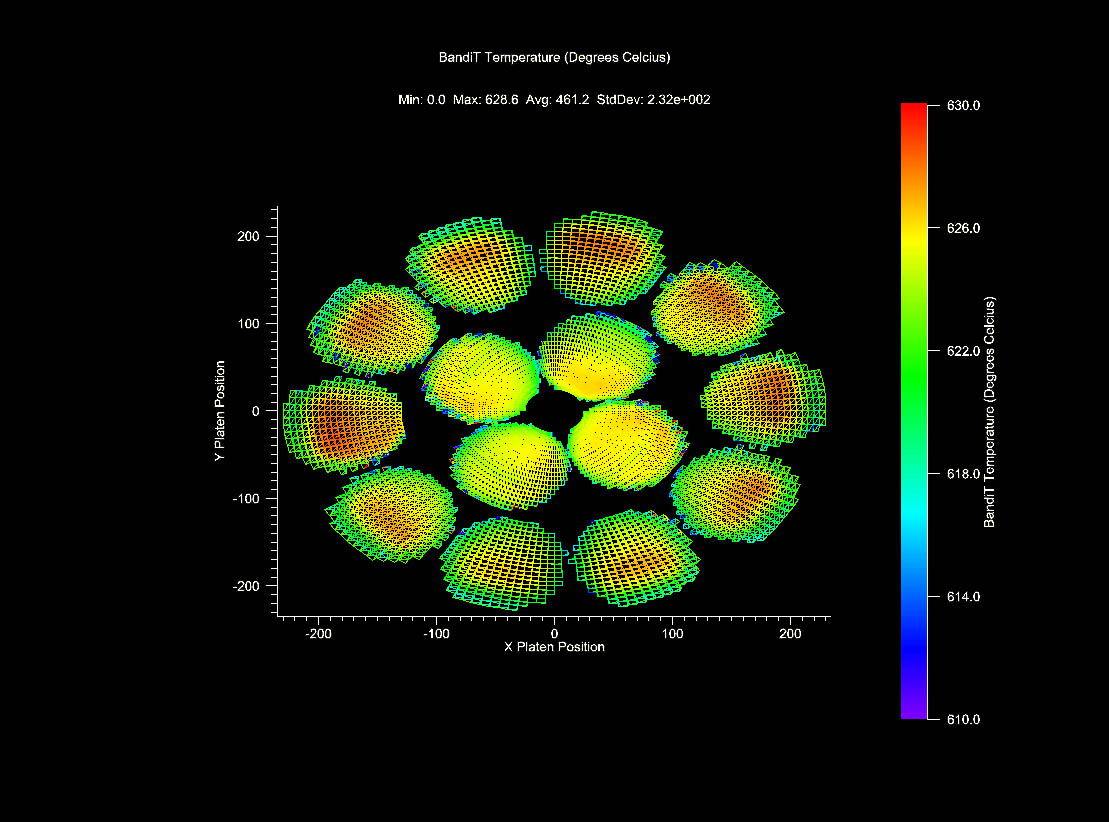

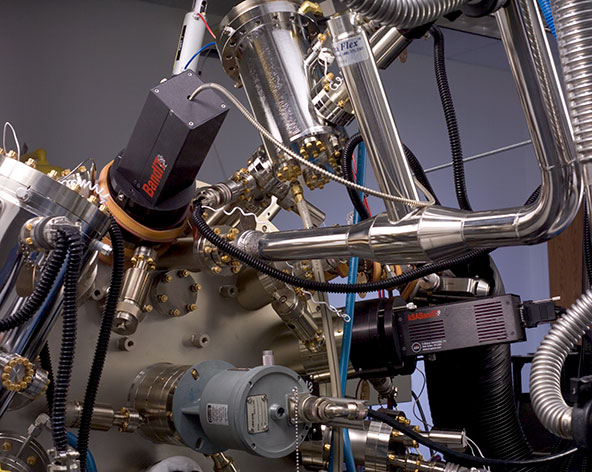

kSA BandiT

In situ thin-film and wafer temperature measurement via Band Edge, Blackbody, and Pyrometry, typically used in MBE, PLD, ALD, sputtering, and e-beam evaporation deposition environment.

kSA BandiT PV

In-line temperature measurement via Band Edge, Blackbody, and Pyrometry, ideal for thin film photovoltaic metrology applications, including in-line production measurement.

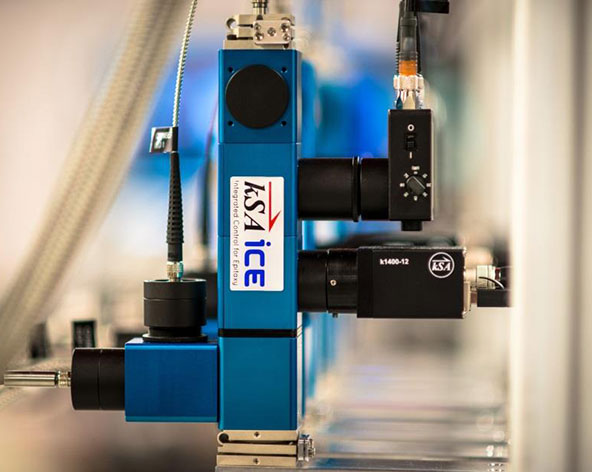

kSA ICE

In situ modular tool for thin-film and wafer temperature measurement via individual Emissivity Corrected Pyrometry (ECP), Blackbody, and/or Band Edge Modules, ideal for MOCVD and MBE reactors with either high speed or low speed rotation and limited optical access.

kSA SpectraTemp

In situ tool for absolute temperature measurement of semiconductor wafers, metals, ceramics, MOCVD carriers, and much more. Can also be used to calibrate pyrometers and other blackbody-like sources.

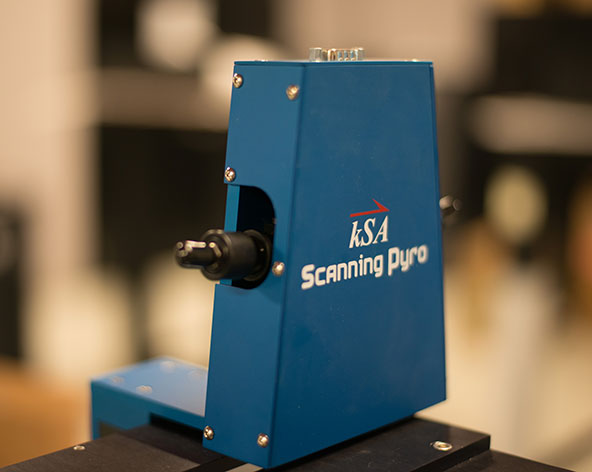

kSA ScanningPyro

In Situ metrology for wafer carrier and wafer temperature measurement, creating high-resolution temperature maps for Veeco K465i and EPIK700 systems. This metrology tool greatly enhances the ability to perform process optimization.