Description

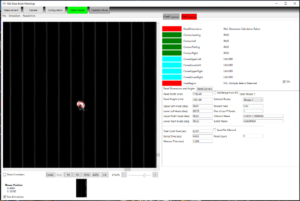

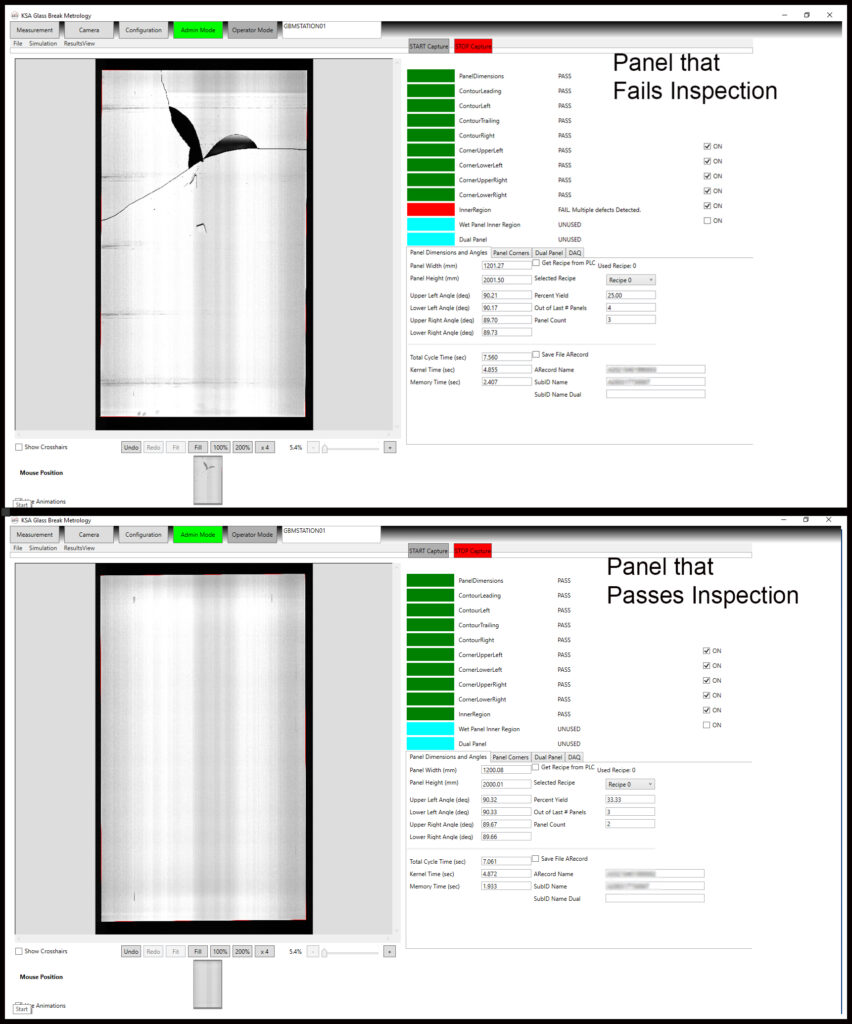

The kSA Glass Breakage & Defect Detection tool is a vision-based metrology system that determines Go/No-Go (Pass/Fail) conditions for every glass lite and panel it inspects inline during processing. The tool accomplishes this by comparing coated or uncoated glass lites and panels against user-defined parameters and tolerances in a master specification reference to identify defects such as cracks, chips, scratches, digs, and pinholes.

The kSA Glass Breakage & Defect Detection tool is a vision-based metrology system that determines Go/No-Go (Pass/Fail) conditions for every glass lite and panel it inspects inline during processing. The tool accomplishes this by comparing coated or uncoated glass lites and panels against user-defined parameters and tolerances in a master specification reference to identify defects such as cracks, chips, scratches, digs, and pinholes.

Details

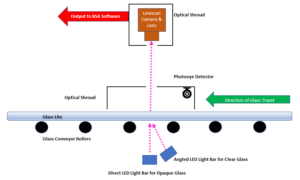

- The custom frame enclosure houses a linescan camera, LED lights, and photoeyes.

- The camera vision system captures images of the panels as they pass by the instrument on a conveyor.

- LED lights illuminate the panels to help distinguish between defects and minor irregularities.

- Photoeyes detect the leading and trailing edges of the panels to trigger the system to start and stop data collection.

- High-resolution encoders trigger spatially-resolved linescans as the panel moves under the LED lighting, generating a high-resolution image of the panel for detailed image processing and defect detection.

- The CPU provides image processing and data storage capabilities.

Benefits

- Real-time visual and data analysis of glass breakage and defects (scratches, digs, cracks, chips, pinholes, etc.) to quickly quarantine or scrap inline defective product as it moves along the line.

- Early detection of defects results in reduced down time and scrap costs.

- Documented compliance with applicable glass visual and safety standards (ASTM, ANSI) ensures consistency across all glass lites and panels.

- Customizable software enables users to configure the settings to fit their specific needs.

- In-process QC validation ensures that all lites and panels conform to the custom master standard.

- Factory integration capabilities enable facilities to incorporate the tool into existing systems (factory alarms, PLC, email alerts, etc.).

Technology

- The custom frame enclosure houses photo eyes, LED lights, and a single line-scan camera.

- Photo eyes detect the leading and trailing edges of the panels and trigger the system to start and stop data collection.

- LED lights illuminate the glass panels from underneath the conveyance system to help distinguish between defects and minor irregularities.

- The camera vision system captures linescan images to identify glass edge dimensions and then captures full area images of the glass lites and panels as they pass by the instrument on a conveyor.

- High-resolution encoders trigger spatially resolved line scans as the panel moves over the LED lighting system, generating a high-resolution image of the panel for detailed image processing and defect detection.

- The CPU provides image processing, data analysis, and data storage capabilities.

Capabilities

- Provides high-resolution line-scan camera system options (up to 1,000 samples/second) to meet desired conveyance line speed and image resolution

- Captures high-resolution glass panel images and stores data for the user-selected lites and panels (failed, random, all, etc.)

- Handles both clear/transparent glass and opaque glass using high-intensity (>14K lux at 500 mm working distance) LED light bar modules with safety shielding

- Includes built-in Calibration/Gage R&R testing

- Starts and stops data acquisition based on triggers from the in-line photo eye detectors

- Allows skew of +/- 5° through the scanning process

- Supports conveyor line speeds ranging from 1 to 36 m/min (balanced against resolution/accuracy requirements)

- Scans clear or coated glass of thicknesses ranging from 2 to12 mm

- Supports tempered or heat-treated glass with distortion of +/- 15 mm

- Measures in situ panels up to 1.2 x 2 m (single camera system) with +/-0.5 mm accuracy

- Supports multiple-lite loads

- Applies a customized reference standard based on pass/fail limits on user-specified parameters and tolerances

- Captures, analyzes, and stores data using proprietary k-Space software

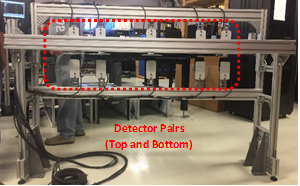

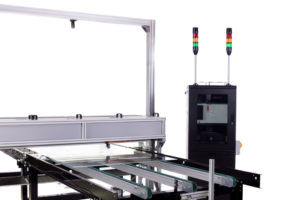

All of this is accomplished through the glass breakage detector, which includes the frame with detectors and standalone electronics cabinet with rackmount CPU, monitor, keyboard, and mouse.

Software

- Fully customizable user interface and data acquisition to meet user needs

- Capable of acquiring data from a live source or a saved data file

- Capable of filtering or smoothing data using a variety of methods and parameters

- Able to write to SQL databases and files for off-line analysis with statistical software tools, such as JMP from SAS

Description

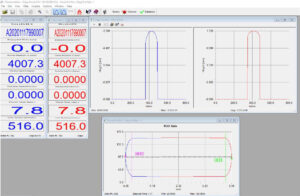

The In Situ Film Thickness metrology tool is a non-contact, non-destructive, real-time thin film characterization sensor that utilizes the detailed spectral analysis of specularly reflected light from the solar panel. This system is designed to monitor film thickness directly on coater tools.

Details

- Proprietary k-Space spectral fringe analysis determines semi-transparent thin-film thickness in real-time.

- k-Space software analyzes the below-gap spectral interference fringes to determine the total film thickness.

- The system acquires spectra data and determines thickness in real-time, all without interfering with the production line.

- Typical systems include 2 probes per tool (left channel and right channel).

- A sapphire reference normalizes the light source output.

- The tool detects panels through a threshold signal level (peak intensity of raw spectrometer signal).

Description

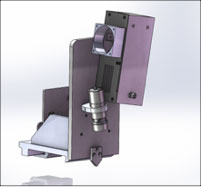

The Inline Film Thickness and Roughness metrology tool is a post-coater metrology tool that analyzes the below-gap spectral interference fringes to determine the total film thickness. In addition, it determines film roughness by inspecting the envelope of the interference spectra.

Details

- The system performs final film thickness and surface roughness measurements after the coating has been applied.

The software utilizes proprietary k-Space spectral fringe analysis.

The software utilizes proprietary k-Space spectral fringe analysis.- Typical systems include 2 probes per tool (left channel and right channel).

- The inline tool includes inline sapphire references that sit approximately 2mm below the bottom surface of the panels.

- The spectrometers are Flat-Field-Corrected (FFC) to ensure proper roughness measurement and tool-to-tool roughness matching.

- The tool detects panels through a threshold signal level (peak intensity of raw spectrometer signal).

Description

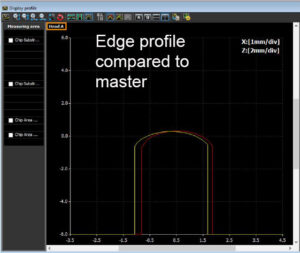

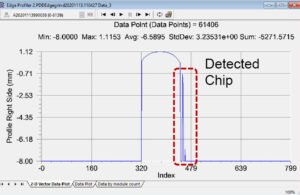

The Edge Profile (“edge grind”) tool is a non-contact, inline glass metrology tool that measures the edge profile of a glass lite or panel. It utilizes a high-resolution 406 nm laser to measure the edge profile of a glass lite or panel as it travels through the process line, while using the software to compare the profile to a master reference profile for compliance. In addition, this tool has the ability to detect chips, cracks, debris, dual pane offset, and shiners on the production line, providing improved real-time quality control.

- The main parameters measured with this tool are edge radius of curvature, chip and crack detection and size, and debris detection.

- The system uses mountable, custom gauge blocks to calibrate each head for height and radius of curvature measurement.

- The tool detects panels through a threshold signal level (peak intensity from reflected laser line profile).

- Standard systems include 2 probes per tool.

Benefits

- Real-time visual and data comparison of glass edge radius profiles and other edge parameters against a master reference profile allows for in-process lite and panel validation and QC.

- Inline identification of edge defects (chips, shiners, etc.) reduces the chance of downstream glass breakage and yield losses.

- Customizable software simplifies the processes by allowing users to enable the specific features that apply to their particular processes.

- The ability to see changes in profile quality enables early detection of grinder wheel wear, which allows for proactive replacement and prevents non-compliant product from entering the process flow.

Technology

Technology

- The tool uses two (2) 406 nm laser line profilometers, mounted on the side of the conveyance system, to detect glass lites and panels through a threshold signal level (peak intensity of reflected laser line profile from the glass edge).

- The signals then produce real-time edge radius and other measurement parameter feedback through k-Space’s proprietary software.

- Users can compare the acquired data against a saved master profile to determine in real-time the pass/fail status of a glass lite or panel. Users can also save the data off-line for deeper QC analysis of the desired datasets.

Capabilities

- Scans clear or coated glass of thicknesses ranging from 2 to 12 mm

- Scans single glass lites or multiple glass panel assemblies with interlayers (glass offset)

- Includes a built-in calibration process

- Uses a customizable master radius reference from a control sample to determine pass/fail limits

- Scans short-edge and long-edge leading profiles (with 90-degree conveyance systems) for full glass profile characterization (4 sensors)

- Standard system includes 2 sensors

- Allows for quick and accurate glass thickness calibration using adjustable gauge mounts

- Identifies inline Panel IDs/Barcodes

- Measures panel width, length, and squareness with 4 sensor system

- Inspects lites and panels to rapidly detect non-compliant edge defects (chips, digs, cracks, and debris) based on preset limits

- Captures, analyzes, and stores data using proprietary k-Space software

- System includes custom frame for your conveyance/factory configuration, standalone electronics cabinet with light tower, and controller

Software

Software

- Fully customizable user interface and data acquisition to meet user needs

- Capable of acquiring and analyzing data from the live source previously saved data file

- Able to characterize full line glass lite and panel profiles (all 4 sides) and display quantitative data by panel

- Capable of filtering or smoothing data using a variety of smoothing and averaging filters

- Ability to write to SQL database and standalone k-Space data files for off-line analysis with statistical software tools, such as JMP

Description

The Transmission metrology tool measures transmission signal directly through the panel. It measures both material band edge (if present) and Integrated Band Absorption (IBA) values simultaneously.

Details

- The tool continually recalibrates between every panel by making a full transmission measurement between panels.

- An integrating sphere on the underside (transmission) collects all signal for proper, absolute transmission and IBA measurement.

- The tool detects panels through a threshold signal level (peak intensity of raw spectrometer signal below between-panel transmission signal).

- Standard systems include 2 probes per tool.

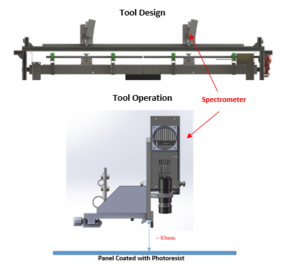

Description

The PhotoResist metrology tool is a non-contact, non-destructive, real-time thin-film characterization system that measures PR (PhotoResist) thickness via a thin film interference fringe analysis from the reflected spectral intensity profile. This is a delta thickness measurement that requires the tool to pre-measure the underlying base film thickness to determine the final thickness of the PR.

Details

- A sapphire reference normalizes the light source output.

- The tool detects panels through a threshold signal level (peak intensity of raw spectrometer signal).

- Standard systems include 2 probes per tool.

Benefits

- Documented compliance with applicable FPD standards (VESA, IDMC) ensures consistency across all panels.

- Real-time monitoring of photoresist thickness against base film thickness allows for immediate feedback.

- The ability to see changes in photoresist thickness and uniformity prevents non-compliant product from entering the process flow.

- Contact-free operation maintains the integrity of the production line.

- Customizable software enables companies to view the parameters they need.

- Factory integration capabilities enable facilities to incorporate the tool into existing systems (factory alarms, PLC, email alerts, etc.).

- The built-in calibration feature simplifies the calibration process.

Description

The Absolute Spectral Reflectance metrology tool measures absolute spectral reflectance to characterize various films, including anti-reflection coatings (ARC). The system utilizes a 390-940nm spectrometer. An internal quartz reference continuously calibrates the absolute reflectance between panels.

Details

- The tool uses an internal quartz reference and beam splitting optics to recalibrate between every panel.

- The tool measures color information (L*a*b* parameters) and scales the values to the sun light output distribution function.

- The optional kSA FitTool simulation and fitting software adds the ability to determine film thickness.

- A sapphire reference normalizes the light output signal.

- The tool detects panels through a threshold signal level (peak intensity of raw spectrometer signal).

- Standard systems include 3 probes per tool.

Description

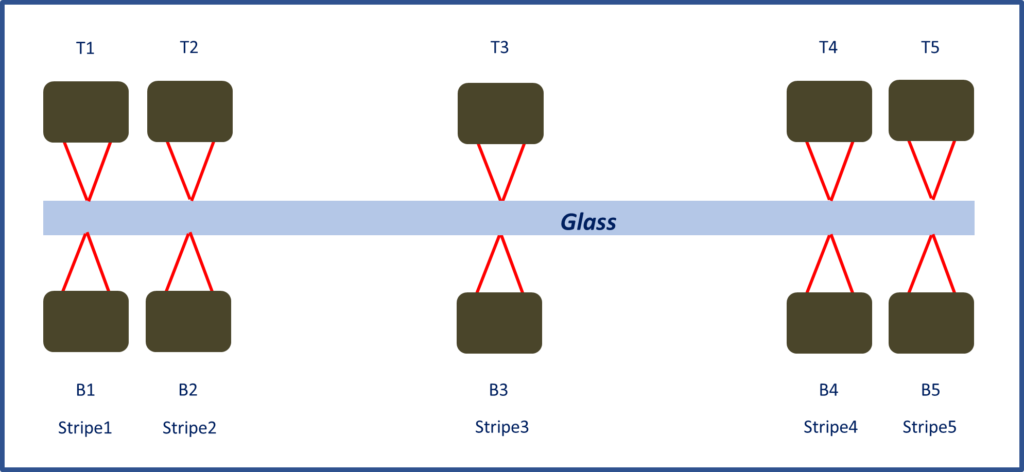

The kSA Glass Thickness and Flatness Tool is an in-line, non-contact metrology tool that measures total glass thickness, flatness (bow, warp, etc.), and total thickness variation (TTV). The tool utilizes 10 laser-based height sensors (5 above and 5 below) to measure at 5 positions along the width of the glass panel. The software deduces bow, warp, and TTV measurements from the individual height measurements and derives the glass thickness from the measured surface heights after the system is calibrated to known thickness standards.

The kSA Glass Thickness and Flatness Tool is an in-line, non-contact metrology tool that measures total glass thickness, flatness (bow, warp, etc.), and total thickness variation (TTV). The tool utilizes 10 laser-based height sensors (5 above and 5 below) to measure at 5 positions along the width of the glass panel. The software deduces bow, warp, and TTV measurements from the individual height measurements and derives the glass thickness from the measured surface heights after the system is calibrated to known thickness standards.

Details

- Colinear laser sensors determine the panel thickness by measuring the panel height on top and bottom. As such, vertical movement/bounce of the panel does not affect the measurement, because the delta height measurement accounts for the height offset.

- The software deduces bow, warp, and TTV measurements from the individual height measurements.

- Standard systems include 10 probes per tool (5 top and 5 bottom, for 5 stripe positions).

Benefits

Documented compliance with applicable glass thickness and bow/warp standards (ASTM, ANSI) ensures consistency across all glass lites and panels.

Documented compliance with applicable glass thickness and bow/warp standards (ASTM, ANSI) ensures consistency across all glass lites and panels.- Real-time data allows for immediate validation of glass thickness and bow/warp across the panel.

- Fully customizable system (hardware and software) enables users to configure the system to fit their specific needs.

- In-process QC validation ensures that all lites and panels conform to the custom master reference substrate (thickness and flatness baseline).

- The ability to see changes in glass thickness and distortion prevents non-compliant product from entering the process flow.

- Factory integration capabilities enable facilities to incorporate the tool into existing systems (factory alarms, PLC, email alerts, etc.).

Technology

- The tool uses 10 laser-based sensors (5 each for top and bottom positions) at 5 set positions, or “stripes,” across the conveyance system.

- The laser pairs measure the distance or height to the glass surface top and bottom to calibrated and known thickness standards for that glass panel as it passes through the system.

- The laser signals then produce real-time glass thickness feedback through k-Space’s proprietary software to provide both immediate viewing in the electronics cabinet as well as data acquisition to the database.

- Users can see the pass/fail status in real-time through comparison of the acquired data against master thickness and flatness criterion, or they can use the stored data for deeper QC analysis of the desired dataset.

Capabilities

- Scans clear or coated single glass lites or multiple glass panel assemblies with interlayers (glass offset) of thicknesses ranging from 2 to 12 mm

- Measures in situ thickness with +/- 5 µm accuracy

- Supports conveyor line speeds ranging from 1 to 36 m/min (balanced against resolution/accuracy requirements)

- Supports distances of up to 60 mm +/- 5 mm from the detector to the glass edge

- Includes a built-in calibration process

- Uses a customizable master thickness and flatness reference from a control sample to determine pass/fail limits

- Allows for customizable measurement locations (5 sites possible) and alignment across conveyor based on needs and requirements

- Identifies inline Panel IDs/Barcodes

- Inspects lites and assemblies to rapidly detect non-compliant thickness and flatness based on preset limits

- Captures, analyzes, and stores data using proprietary k-Space software

All of this is done through the kSA Glass Thickness and Flatness system, which includes the frame with detectors and a standalone electronics cabinet that houses the rackmount CPU, monitor, keyboard, and mouse.

Description

Description

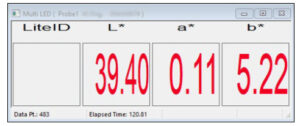

The reflectance color metrology (kSA RCM) tool is designed to obtain absolute, real-time spectral reflectance information and color parameters to ensure color consistency across glass lite panels. It collects reflected light from a lite panel and then measures its absolute spectral reflectance to check for color consistency across panels on a production line. The kSA RCM is capable of continuously acquiring a true absolute spectral measurement.

Details

- The kSA RCM has a single optics head attached to a dual linear stage system to scan the panel.

- The optics head to panel distance is maintained at a constant distance, even with varying panel position/warp, by utilizing ultrasonic sensors and a horizontal stage for continuous optics head position adjustment.

- The metrology sends a beam of light incident on the panel. The spectrometer collects this reflected light, and the k-Space software analyzes the collected data. The software calculates the reflectance and color values from the spectra. This color measurement can be designed to output in the user’s preferred format CIE L*a*b*, or other.

- The kSA RCM collects and stores data, and it can interface with the user’s QC system, PLC, or factory database.

Benefits

- The tool ensures consistent color with immediate process feedback for control, which is essential to high yield and quality.

- This system can interface with existing QC systems, and operators can view and analyze data on the production floor.

- k-Space can incorporate Go/No go (pass/fail) or other alarms into this system.

Technology

Technology

- The optics head consists of a light source, a collection lens, a spectrometer, and other proprietary components.

- The system incudes 2 linear stages — one for scanning and one for height adjustment to ensure the proper head-to-sample distance for accurate readings.

- The electronics cabinet accommodates any user-specified alarm stations, real-time readouts, and access to stored data. The data can interface with existing QC systems.

Capabilities

Capabilities

- The system is designed for automated measurement. However, if desired, the operator can manually move the head to any point within the stage limits to take measurements or to access a specific point in the conveyor.

- Auto-focus capability enables real-time sample-to-detector measurement and head position adjustment.

- Automated dark background and reference acquisition capabilities ensure accuracy of the data.

- The software can display color and reflectance data in real-time plots and simple number values.

- Alarm trigger capabilities include built-in go/no go options.

- Real-time process feedback can draw the operator’s attention to issues that require reflectance and color adjustments.

Software

Software

- Windows-based software can run in Engineer or Operator mode. The Operator mode is limited to basic options to simplify use on factory floor.

- The software can display real-time acquisition charts that plot absolute reflectance and color trends.

- The software can also display data as real-time digital readouts.

Description

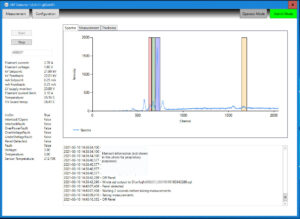

The kSA XRF (X-Ray fluorescence) tool measures the layer thickness of film on glass and solar panels that are too thin for reliable optical measurements. It uses an X-ray source, detector, and sophisticated software to measure the X-ray emission spectrum to calculate film thickness. This tool can be integrated into existing QC systems, along with the appropriate alarms, to flag thickness issues.

Details

- A protective custom frame enclosure houses the X-ray source and detector.

- The tool bridges over conveyor lines for easy installation and future factory access to the conveyor line.

- An illuminated sign indicates when the X-Ray source is in use.

- Photo eyes detect the leading and trailing edges of the panels to trigger the system to start and stop data collection.

- The electronics cabinet CPU provides processing and data storage capabilities.

- The light tower gives go/no go indications.

Benefits

- This technology allows for the measurement of dielectric coatings that are too thin for optical measurements such as those below roughly 100 nm.

- Can also provide a thickness on thin metal films on various substrates.

- Real-time data acquisition provides immediate detection of defects in the coating thickness and feedback control.

- Customizable software enables users to configure the settings to fit their specific needs.

- In-process QC validation ensures that coating thickness is within tolerances.

- Factory integration capabilities enable manufacturers to incorporate the metrology into existing systems (factory alarms, PLC, email alerts, etc.).

- Straightforward functionality requires little to no operator interface and only occasional operator calibration.

Technology

- The system is comprised of an X-ray tube with a high voltage generator along with an X-ray detector system. The X-ray detection system is a combined solid-state detector, amplifier, pulse height analyzer, and multichannel analyzer.

- Following spectrometer energy calibration, the system identifies the spectral peaks of the X-ray emission spectrum and collects the peak intensities for further processing.

- The tool measures the appropriate atomic species, based on the customer’s coating formula and measurement needs.

Capabilities

- Measures, analyzes, and stores data using proprietary k-Space software.

- Can interface with existing QC systems.

- Starts and stops data acquisition based on triggers from the in-line photo eye detectors.

- Designed for typical glass and solar panel conveyor speeds.

- Fully automated and able to communicate with factory automation.

- Warning and alarm signals are fully configurable through the easy-to-use software.

- The single detector head can be positioned at any location across the panel width, and multiple detector heads are possible.

- A measurement range of 0-500 nm (+/- 1 nm) is possible. The sensitivity and measurement uncertainty depends on the element measured.

Software

- Windows-based software can run in Engineer or Operator mode. The Operator mode is limited to basic options to simplify use on factory floor.

- The software can display real-time acquisition charts to provide the coating thickness.

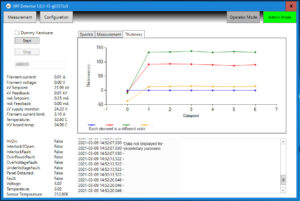

Description

Description

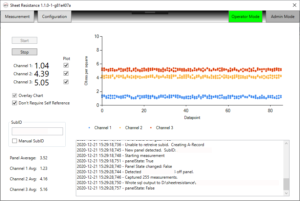

The kSA Inline Sheet Resistance Metrology system monitors the thin film sheet resistivity on glass panels that pass through the system. Sheet resistance (also known as surface resistance or surface resistivity) is a common electrical property used to characterize thin films of conducting and semiconducting materials to determine end product performance. It is a measure of the lateral resistance through a thin square of material, i.e., the resistance between opposite sides of a square. The system consists of three pairs of sensor probes that are mounted on a conveyor support. It is Ideal for flat panel display, solar, and other coated glass applications.

Benefits

- Real-time data validation of sheet resistance conductivity across panel allows for down-stream processing and analysis.

- Real-time monitoring allows immediate analysis of sheet resistance conductivity of thin-film coated panels.

- Fully customizable system (hardware/software) enables users to configure settings to fit their specific needs.

- In-process comparison of live data against a master reference substrate (nominal and tolerances) provides QC validation during panel processing.

- The ability to see changes in sheet resistance that could affect end product performance prevents non-compliant product from entering the process flow.

- Factory integration capabilities enable facilities to incorporate the tool into existing systems (factory alarms, PLC, email alerts, etc.).

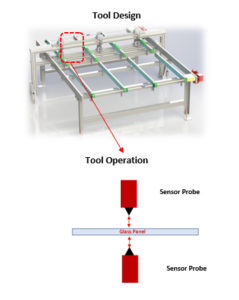

Technology

Technology

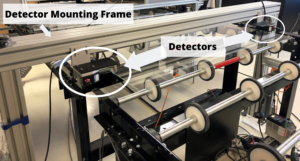

The tool consists of three pairs of sensor heads that are mounted on a conveyor support. Each pair has a pole piece separation of 25mm, and panels pass through at approximately the center point of this space.

The system uses the Eddy-Current system approach to measure sheet resistance in a non-contact manner.

- The top sensor probe acts as the exciter coil and sends a high-frequency magnetic field that induces oscillating current within the conductive material to be measured.

- The bottom sensor probe acts as the measurement coil. When a material is present on the conveyor, the system measures the modified amplitude and phase of the signal in the measurement coil and then compares that against a set of calibration standards to calculate the sheet resistance of the material.

Capabilities

Capabilities

- Scans single-coated glass (with a conductive layer) of glass thicknesses ranging from 2 to 12 mm

- Standard product measures in situ sheet resistance range of 1-100 Ω/□ with +/- 0.05 Ω/□ Measurements in other resistance ranges are possible. Please contact kSA with requirements.

- Includes a self-calibration step at periodic intervals in between sample measurements.

- Uses a customizable master sheet resistance value (Ω/□) and tolerance range from a control sample to determine pass/fail limits

- Allows for customizable measurement locations (3 sites possible) and alignment across the conveyor based on needs and requirements

- Identifies inline Panel IDs/Barcodes (add-on functionality option)

- Detects drift in conductive coating thickness across and potential impacts to end product performance

- Inspects lites and panels to quickly identify non-compliant coated glass sheet resistance and conductivity values, based on preset limits

- Captures, analyzes, and stores data using proprietary k-Space software

All of this is done through the kSA Inline Sheet Resistance system, which includes the frame with detectors and standalone electronics cabinet with rackmount CPU, monitor, keyboard, and mouse.

The solar industry is quite competitive and with that comes the need for thin film solar companies to continuously improve their processes and products. Our solar panel inspection tools will help you improve quality and increase throughput.

k-Space is constantly developing new photovoltaic (PV) metrology for thin film solar cell manufacturing. Currently, we have the proven capability to measure various parameters on frame components, bare glass, coated glass, and fully assembled panels, as well as edge profile inspection. We can customize our metrology to tackle your specific needs in any of these areas.

Here is a look at some of the solar panel inspection tools and custom capabilities we offer with our tools:

- Detect oil contamination and other cosmetic defects through the use of line scan cameras with UV and white light sources.

- Detect chips, cracks, contaminants, and panel dimensions through the use of line scan cameras with white light illumination.

- Examine edge contour, defects, and dimensions through edge profile inspection through the use of laser-based metrology.

- Measure and control uniformity, thickness, band gap, temperature, surface roughness, and more through the use of patented kSA BandiT technology.

Our PV metrology solutions for measuring edge sealant, edge profiler, and edge pinch were featured in a laser-based PV metrology poster presented at the 2018 NREL PV Reliability Workshop.

What are your measurement challenges? k-Space loves designing custom metrology to help you gain insight into your process and achieve your goals.

To see other inline metrology solutions, visit our industrial metrology page.

Ask an engineer about your solar panel inspection and measurement needs now.