Obtain absolute, real-time spectral reflectance information and color parameters. Real-time acquisition charts plot absolute reflectance and color trends.

Description

The reflectance color metrology (kSA RCM) tool is designed to obtain absolute, real-time spectral reflectance information and color parameters to ensure color consistency across glass lite panels. It collects reflected light from a lite panel and then measures its absolute spectral reflectance to check for color consistency across panels on a production line. The kSA RCM is capable of continuously acquiring a true absolute spectral measurement.

Details

- The kSA RCM has a single optics head attached to a dual linear stage system to scan the panel.

- The optics head to panel distance is maintained at a constant distance, even with varying panel position/warp, by utilizing ultrasonic sensors and a horizontal stage for continuous optics head position adjustment.

- The metrology sends a beam of light incident on the panel. The spectrometer collects this reflected light, and the k-Space software analyzes the collected data. The software calculates the reflectance and color values from the spectra. This color measurement can be designed to output in the user’s preferred format CIE L*a*b*, or other.

- The kSA RCM collects and stores data, and it can interface with the user’s QC system, PLC, or factory database.

Benefits

- The tool ensures consistent color with immediate process feedback for control, which is essential to high yield and quality.

- This system can interface with existing QC systems, and operators can view and analyze data on the production floor.

- k-Space can incorporate Go/No go (pass/fail) or other alarms into this system.

Capabilities

- The system is designed for automated measurement. However, if desired, the operator can manually move the head to any point within the stage limits to take measurements or to access a specific point in the conveyor.

- Auto-focus capability enables real-time sample-to-detector measurement and head position adjustment.

- Automated dark background and reference acquisition capabilities ensure accuracy of the data.

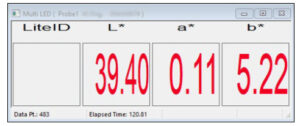

- The software can display color and reflectance data in real-time plots and simple number values.

- Alarm trigger capabilities include built-in go/no go options.

- Real-time process feedback can draw the operator’s attention to issues that require reflectance and color adjustments.

Software

- Windows-based software can run in Engineer or Operator mode. The Operator mode is limited to basic options to simplify use on factory floor.

- The software can display real-time acquisition charts that plot absolute reflectance and color trends.

- The software can also display data as real-time digital readouts.

Technology

- The optics head consists of a light source, a collection lens, a spectrometer, and other proprietary components.

- The system incudes 2 linear stages — one for scanning and one for height adjustment to ensure the proper head-to-sample distance for accurate readings.

- The electronics cabinet accommodates any user-specified alarm stations, real-time readouts, and access to stored data. The data can interface with existing QC systems.