Measures the layer thickness of film on glass and solar panels to below 100 nanometers. Measurement of dielectric coatings that are too thin for optical measurements.

Description

The kSA XRF (X-Ray fluorescence) tool measures the layer thickness of film on glass and solar panels that are too thin for reliable optical measurements. It uses an X-ray source, detector, and sophisticated software to measure the X-ray emission spectrum to calculate film thickness. This tool can be integrated into existing QC systems, along with the appropriate alarms, to flag thickness issues.

Details

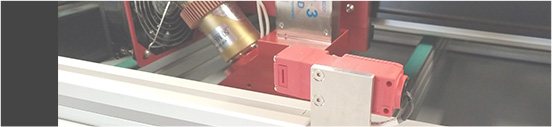

- A protective custom frame enclosure houses the X-ray source and detector.

- The tool bridges over conveyor lines for easy installation and future factory access to the conveyor line.

- An illuminated sign indicates when the X-Ray source is in use.

- Photo eyes detect the leading and trailing edges of the panels to trigger the system to start and stop data collection.

- The electronics cabinet CPU provides processing and data storage capabilities.

- The light tower gives go/no go indications.

Benefits

- This technology allows for the measurement of dielectric coatings that are too thin for optical measurements such as those below roughly 100 nm.

- Can also provide a thickness on thin metal films on various substrates.

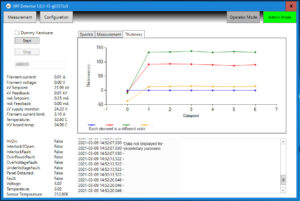

- Real-time data acquisition provides immediate detection of defects in the coating thickness and feedback control.

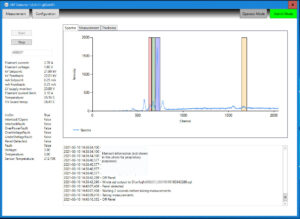

- Customizable software enables users to configure the settings to fit their specific needs.

- In-process QC validation ensures that coating thickness is within tolerances.

- Factory integration capabilities enable manufacturers to incorporate the metrology into existing systems (factory alarms, PLC, email alerts, etc.).

- Straightforward functionality requires little to no operator interface and only occasional operator calibration.

Capabilities

- Measures, analyzes, and stores data using proprietary k-Space software.

- Can interface with existing QC systems.

- Starts and stops data acquisition based on triggers from the in-line photo eye detectors.

- Designed for typical glass and solar panel conveyor speeds.

- Fully automated and able to communicate with factory automation.

- Warning and alarm signals are fully configurable through the easy-to-use software.

- The single detector head can be positioned at any location across the panel width, and multiple detector heads are possible.

- A measurement range of 0-500 nm (+/- 1 nm) is possible. The sensitivity and measurement uncertainty depends on the element measured.

Technology

- The system is comprised of an X-ray tube with a high voltage generator along with an X-ray detector system. The X-ray detection system is a combined solid-state detector, amplifier, pulse height analyzer, and multichannel analyzer.

- Following spectrometer energy calibration, the system identifies the spectral peaks of the X-ray emission spectrum and collects the peak intensities for further processing.

- The tool measures the appropriate atomic species, based on the customer’s coating formula and measurement needs.