Application Notes : kSA BandiT– GaN BandiT Temperature Monitor

Version: 1.0

- kSA GaN BandiT Temperature Monitor

- Band Edge Technology

- BandiT Chamber Mounting Options

- Conditioning for GaN Use

- GaN BandiT MOCVD Configuration

- MOCVD Growth Results

- MBE Growth Results

- Summary

kSA GaN BandiT Temperature Monitor

Measure GaN Not The Holder!

- Successful MOCVD and MBE results

- SSP Sapphire

- DSP 4H and 6H Silicon Carbide

- Real-time surface temperature effects directly measured

- Multi-wafer capability with individual wafer resolution

- Within wafer temperature effects now measured

Introduction

GaN-based LEDs and power electronics are currently a very active area for research, development, and production. While accurate and reproducible substrate temperature measurement is imperative for improved process control, and ultimately better device performance, current technology is insufficient for accurate and reproducible wafer temperature measurement. All forms of pyrometry, including emissivity-corrected pyrometers (ECPs), rely upon technology that measures black body radiation from the sample, which occurs at wavelengths that are transparent to GaN and SiC materials due to their large band gap. Therefore, all current temperature measurements are based upon the radiation from the heater or the susceptor (in MOCVD) behind the sample, and do not make a direct temperature measurement of the sample itself.

One of the key strengths of the kSA BandiT system is that it measures a fundamental material property of the wafer, namely, the temperature-dependent band gap. This measurement is manifested through the monitoring of the absorption edge of the material and is not intensity dependent, as a pyrometer reading is. In the case of GaN deposited on sapphire, kSA BandiT measures the temperature of the GaN film itself and not that of the susceptor, heater, or substrate. (Sapphire is an insulator and does not have a measurable band gap.) Because SiC is a semiconductor with similar band gap to GaN, the same hardware may be used when using SiC as a substrate for GaN-based films. As such, the measurement is not affected by changing view port transmission, stray IR sources, changing reactor emissivity, and so on. In addition, never before measured changes in temperature due to gas flow convection or substrate bowing are now possible, yielding a novel method for measuring the true temperature of GaN epiwafers.

Band Edge Technology

The kSA BandiT is a non-contact, non-invasive, real-time, absolute wafer temperature sensor utilizing the temperature-dependent absorption edge of semiconductor materials to determine substrate temperature. The absorption edge position is directly related to the band gap energy of the material, which, in turn, is temperature dependent. While both empirical and theoretical equations exist for band gap dependence on temperature for most materials of interest, in practice these equations do not consider doping effects, scattering, and instrument response. As a result, it is more accurate to generate experimental calibration curves or lookup tables that map a measured absorption edge wavelength to a previously calibrated temperature value.

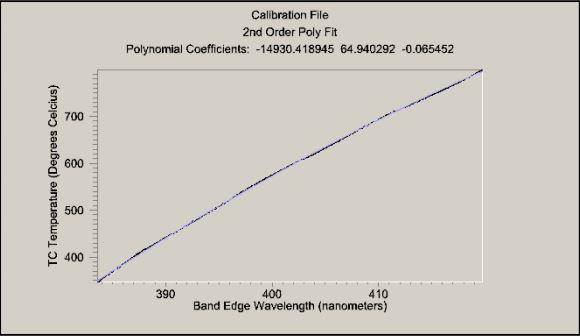

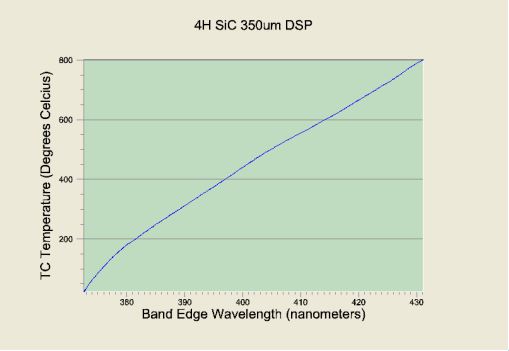

k-Space has developed an empirical method for calibrating the band edge temperature dependence of a particular wafer with that of a NIST traceable black body source (Figure 1). Subsequent temperature measurements using the BandiT system are based upon this direct temperature vs. band edge relationship. No further calibrations are required prior to or during growth of GaN films for reproducible temperature measurement.

BandiT Chamber Mounting Options

The kSA BandiT can be operated in two modes:

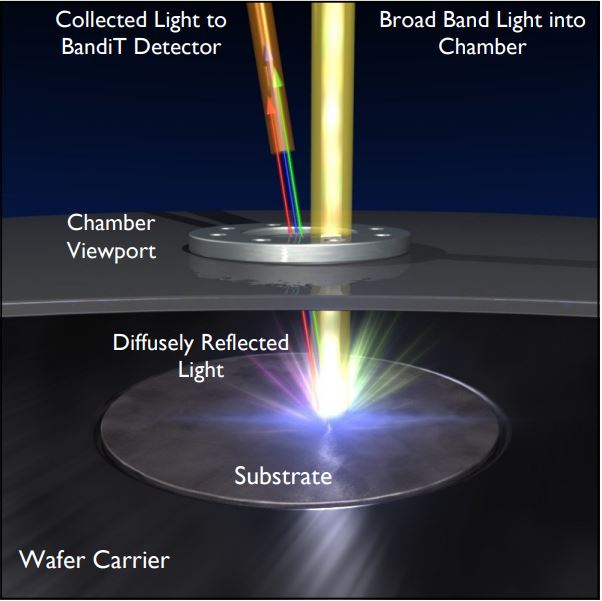

- Reflection mode: (shown in Figure 2) A broadband light source is mounted along with the BandiT detector at non-specular angles. This configuration is for monitoring traditional materials requiring band edge versus temperature detection at shorter wavelengths (i.e. GaN, SiC, ZnO) via a tailored spectrometer. Both dual port and single port options are available to suit most commercial MBE and MOCVD reactors.

- Transmission mode: The substrate heater is used as the light source for band edge versus temperature applications covering the IR spectral range (i.e. GaAs, InP, & Si). A secondary light source is not required.

Conditioning for GaN Use

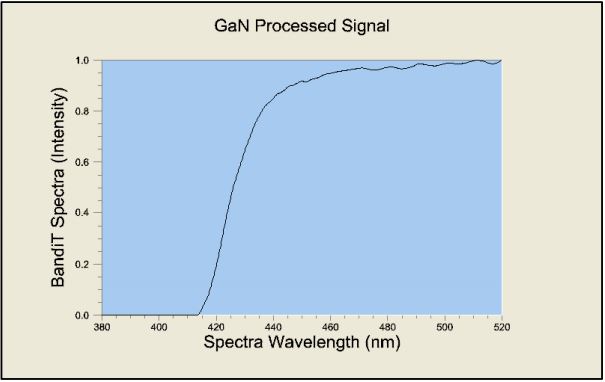

The kSA BandiT response in the short wavelength regime is nonlinear, meaning the light source has lower output power and the spectrometer has lower sensitivity at shorter wavelengths (380- 520nm). To resolve this, the instrument response must be divided out of the signal to see a clear absorption edge. This is done by taking a room temperature reference spectra with the lamp set to the power level that will be used during subsequent temperature monitoring. The spectra acquired from the sample is then divided by the reference spectra in order to obtain the absorption edge position. The absorption edge is clearly seen after the reference divide and subsequent processing (Figure 3). The system is now ready for GaN film temperature monitoring.

GaN BandiT MOCVD Configuration

The GaN BandiT system was mounted on an multi-wafer Aixtron production MOCVD reactor, used for GaN growth (Figure 4). The light source and detector were engineered to facilitate mounting onto a single 1.33” CF or similar view port at normal incidence to the wafer surface. The light source used was a modified liquid light guide apparatus which enabled excellent coupling of the broadband light to the growth surface, and was mounted at normal incidence to the wafer surface. The detector was mounted slightly off axis to minimize specular light from the light source and the integrated laser spot alignment process was used to determine detector spot position and size. As with most HBLED device growth, SSP Sapphire substrates were used. This provides an optimized configuration for maximizing diffusely reflected light signal into kSA BandiT due to the rough surface of the substrate and close proximity to the wafer surface. Planetary rotation of wafers within the system did not affect temperature measurements with kSA BandiT.

MOCVD Growth Results

In order to evaluate kSA BandiT for MOCVD growth, the system was tested under various conditions encountered during optical device growth (i.e. HBLEDs and laser diodes). This included a temperature ramp to growth temperature, GaN and InGaN deposition, and subsequent analysis of individual wafer temperature information.

The Aixtron MOCVD reactor tested had multiple wafers loaded into the susceptor and was typically rotated below 15 rpm. The Aixtron system features gas foil rotation, so each wafer rotates rapidly with its holding pocket, in addition to the slower rotation speed of the entire susceptor. The kSA GaN BandiT was able to spatially resolve temperatures from all wafers during rotation. The data acquired shows that the gas foil rotation has no bearing on the absolute BandiT temperature measurement. This result is to be expected because the diffuse reflectance method is not sensitive to angular variation, especially on SSP substrates.

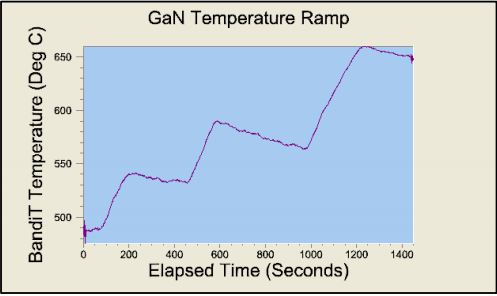

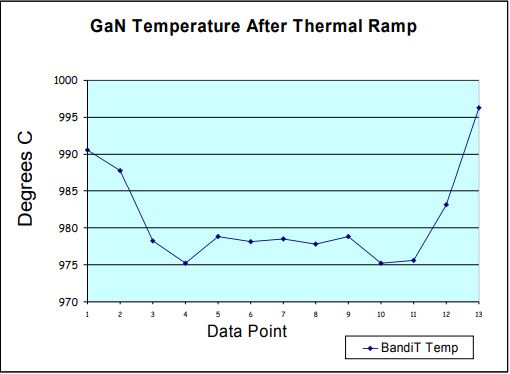

Figure 5 shows BandiT data during a temperature ramp. Note that the apparent noise in the data is not noise at all, but rather variations in temperature between wafers (see inset). The data taken here shows approximately 12 temperature measurements per wafer, yielding spatially-resolved temperature measurement. Note that the temperature profiles shown in Figure 5 are repeatable over longer time scales than those shown.

In order to observe the effect more closely, individual wafer temperature data was extracted from the BandiT software to yield the spatially-resolved temperature information. Data was taken during rotation for a constant thermocouple (TC) and pyrometry temperature of 950°C, just after initial thermal ramping. The BandiT system was configured to take 12-13 measurements per wafer. While constant temperature was measured with both the TC and pyrometer, Figure 6 shows a clear thermal gradient from

edge (10°C hotter) to center (cooler with localized hot spots). These results were most likely from the physical contact variations between the substrate and the susceptor encountered due to substrate bowing. BandiT was able to discern the data between occupied or empty wafer positions within the platen, resulting in temperature data from wafers only.

Since InGaN has a smaller band gap than GaN (expected to absorb the GaN signal), 1000Å of material was grown to validate continued observance of a strong band edge signal required for temperature measurement. The data in Figure 7 shows no change in temperature during the deposition, which is to be expected due to the absence of additional IR absorption from the InGaN layer compared to the GaN layer. The data shown here is a subset of a longer data set that shows the same temperature profile. A total of 1000Å of InGaN was deposited. Note that the raw BandiT spectra signal was decreased by about 20% during the deposition of the InGaN layer (due to absorption from the smaller band gap over-layer), but this did not affect the BandiT temperature determination as the calculation is not signal-level dependent. Interestingly, during the InGaN deposition, kSA BandiT actually measured a slight temperature increase at the wafer surface vs. a decrease read via the pyrometer, which is consistent with the expected outcome vs. the false reading from the pyrometer.

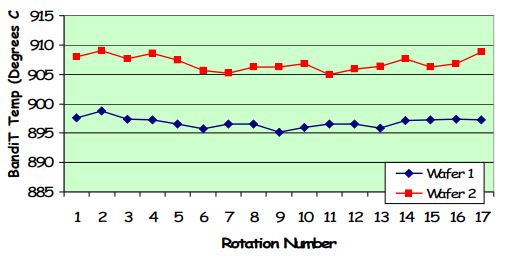

Finally, temperature data was extracted for two separate wafers to illustrate how BandiT would be used in a production MOCVD system (see Figure 8). Since BandiT is able to optically resolve multi-wafer temperatures, individual wafer temperatures at any point on the wafer can be measured, sorted, and output to the appropriate control system.

Figure 5: MOCVD temperature ramp and stabilization with multi wafer temperature detection

Figure 5: MOCVD temperature ramp and stabilization with multi wafer temperature detection

Figure 6: Spatially resolved 2” wafer surface temperature during MOCVD planetary rotation

Figure 6: Spatially resolved 2” wafer surface temperature during MOCVD planetary rotation

Figure 7: 1000 Å InGaN growth on single wafer GaN. Temperature gradients across wafer yield oscillations

Figure 7: 1000 Å InGaN growth on single wafer GaN. Temperature gradients across wafer yield oscillations

Figure 8: Wafer center point temperature extracted for two separate wafers on susceptor

Figure 8: Wafer center point temperature extracted for two separate wafers on susceptor

MBE Growth Results

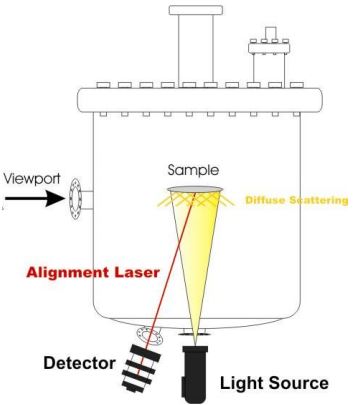

The GaN BandiT system was tested on a Veeco GEN 200 MBE reactor equipped with an RF Nitrogen plasma source and solid source effusion cells. The standard light source was mounted on a 2.75” view port at normal incidence to the substrate, and the detector was mounted on a 2.75” view port at ~18° with respect to the normal of the substrate (Figure 9). After conditioning the system for use with GaN, data was gathered for both GaN on sapphire and SiC substrates.

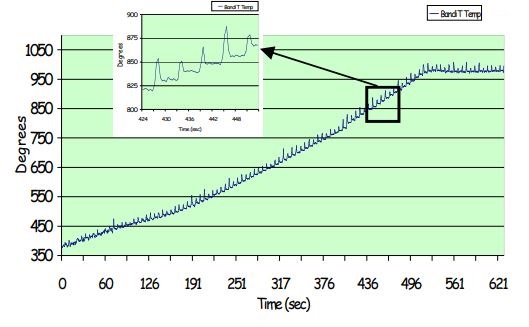

Typical data during 50°C ramp intervals is shown in Figure 10. Note that although the TC reading is stable at each plateau, the actual sample temperature decreases during soak time.

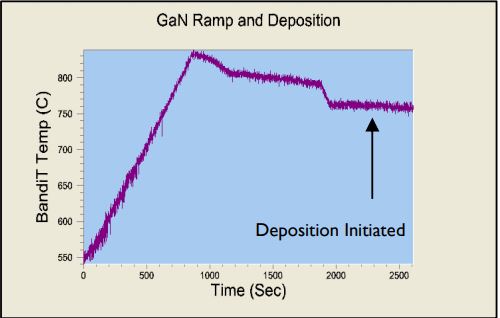

BandiT data was acquired during GaN deposition to determine the effect of the Gallium source and RF Nitrogen plasma source on the temperature measurement. Figure 11 shows the pre-growth temperature ramp of the GaN template, then a cooling, and finally the commencement of deposition at 2395 seconds. There was no difference in the temperature data when the growth commenced. Note also that an initial ~5 seconds of pure Gallium growth occurs before the Nitrogen plasma is opened, to ensure wetting of the surface so subsequent stoichiometric GaN can be grown. This initial Gallium wetting also does not effect the BandiT measurement. Temperature was monitored for 2.3 hrs during deposition, corresponding to approximately 1.2µm of additional GaN film. We saw no appreciable change in temperature, indicating that there was no significant change in absorption due to additional GaN material.

For those using SiC wafers for GaN MBE, we evaluated double-side polished 4H SiC substrates with metal back coat. The DSP surface was mirror-like, reflecting much of the incident light. However, by using the same methodology of reference dividing the background, a clear band edge was observed for direct temperature measurement via the SiC substrate itself (Figure 12). Because the band gap of SiC is similar to that of GaN, the same BandiT system hardware may be used.

GaN BandiT: Summary

This study has shown a novel GaN wafer surface temperature measurement capability for MBE and MOCVD with the kSA BandiT system. Never before has a technique been able to measure temperature variations at the GaN surface level in real time. This approach yields a superior method to any other form of temperature monitoring of GaN films on sapphire or SiC substrates. Also, because BandiT is not affected by changing view port transmission, stray IR sources, or reactor emissivity, it presents a strong case for use in the production of today’s GaN based devices. Please contact your local k-Space Associates’ representative for more information.