Projected growth in US-made solar panels and semiconductor chips leads to increased sales of k-Space metrology solutions

Recent passage of both the CHIPS & Science Act and the Inflation Reduction Act is driving an uptick in sales and opportunities for k-Space, the US-based maker of advanced metrology tools. Both solar panel companies and semiconductor chip makers use k-Space tools to monitor production, uncover potential defects, inspect finished products, and minimize returns.

k-Space CEO Darryl Barlett stated, “thanks in part to the passage of these new laws, our existing solar and semiconductor customers have recently increased orders. Plus, we’ve received numerous inquiries from other companies seeking to expand US-based production in these markets.”

The Inflation Reduction Act allocates billions of dollars for solar panel companies to expand manufacturing in the United States. These companies integrate k-Space metrology tools into their manufacturing lines to measure panel efficiency, dimensions, optical properties, and more.

The CHIPS & Science Act includes $39 billion in grants to expand American semiconductor manufacturing. Semiconductor makers integrate k-Space metrology solutions in their operations to measure wafer temperature, film thickness, stress, curvature, surface roughness, and more. These measurements help improve quality, increase production, and prevent defective chips from leaving the facility.

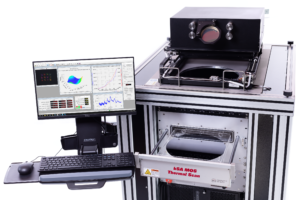

k-Space metrology tools are installed in thousands of manufacturing facilities and research labs across the United States and around the world. To learn more, visit www.k-space.com.