Measures the edge profile of a glass lite or panel as it travels through the process line. Scans clear or coated glass of thicknesses ranging from 2 to 12 mm.

Description

The Edge Profile tool is a non-contact, inline glass metrology tool that measures the edge profile of a glass lite or panel. It utilizes a high-resolution 406 nm laser to measure the edge profile of a glass lite or panel as it travels through the process line, while using the software to compare the profile to a master reference profile for compliance. In addition, this tool has the ability to detect chips, cracks, debris, dual pane offset, and shiners on the production line, providing improved real-time quality control.

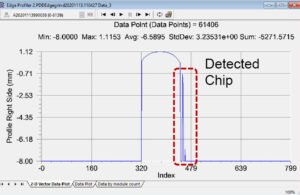

- The main parameters measured with this tool are edge radius of curvature, chip and crack detection and size, and debris detection.

- The system uses mountable, custom gauge blocks to calibrate each head for height and radius of curvature measurement.

- The tool detects panels through a threshold signal level (peak intensity from reflected laser line profile).

- Standard systems include 2 probes per tool.

Benefits

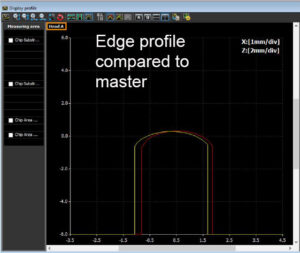

- Real-time visual and data comparison of glass edge radius profiles and other edge parameters against a master reference profile allows for in-process lite and panel validation and QC.

- Inline identification of edge defects (chips, shiners, etc.) reduces the chance of downstream glass breakage and yield losses.

- Customizable software simplifies the processes by allowing users to enable the specific features that apply to their particular processes.

- The ability to see changes in profile quality enables early detection of grinder wheel wear, which allows for proactive replacement and prevents non-compliant product from entering the process flow.

Capabilities

- Scans clear or coated glass of thicknesses ranging from 2 to 12 mm

- Scans single glass lites or multiple glass panel assemblies with interlayers (glass offset)

- Includes a built-in calibration process

- Uses a customizable master radius reference from a control sample to determine pass/fail limits

- Scans short-edge and long-edge leading profiles (with 90-degree conveyance systems) for full glass profile characterization (4 sensors)

- Standard system includes 2 sensors

- Allows for quick and accurate glass thickness calibration using adjustable gauge mounts

- Identifies inline Panel IDs/Barcodes

- Measures panel width, length, and squareness with 4 sensor system

- Inspects lites and panels to rapidly detect non-compliant edge defects (chips, digs, cracks, and debris) based on preset limits

- Captures, analyzes, and stores data using proprietary k-Space software

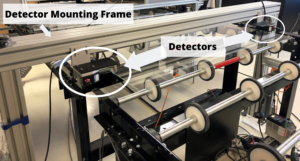

- System includes custom frame for your conveyance/factory configuration, standalone electronics cabinet with light tower, and controller

Software

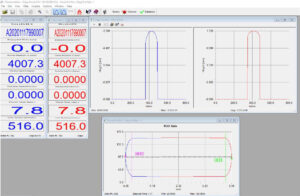

- Fully customizable user interface and data acquisition to meet user needs

- Capable of acquiring and analyzing data from the live source previously saved data file

- Able to characterize full line glass lite and panel profiles (all 4 sides) and display quantitative data by panel

- Capable of filtering or smoothing data using a variety of smoothing and averaging filters

- Ability to write to SQL database and standalone k-Space data files for off-line analysis with statistical software tools, such as JMP

Technology

- The tool uses two (2) 406 nm laser line profilometers, mounted on the side of the conveyance system, to detect glass lites and panels through a threshold signal level (peak intensity of reflected laser line profile from the glass edge).

- The signals then produce real-time edge radius and other measurement parameter feedback through k-Space’s proprietary software.

- Users can compare the acquired data against a saved master profile to determine in real-time the pass/fail status of a glass lite or panel. Users can also save the data off-line for deeper QC analysis of the desired datasets.