Application Notes : kSA BandiT– SiC Temperature Measurement

Version: 1.0

- SiC Temperature Measurement with kSA BandiT

- Measuring SiC Substrate Temperature

- Multiwafer MOCVD Results

- Substrate Polishing & Coating Effects with MBE

- Measure SiC Substrate Temperature Directly

SiC Temperature Measurement with kSA BandiT

Direct Temperature Measurement Of SiC Substrates

- 4H or 6H SiC DSP substrates can now be measured with kSA BandiT

- Strong signal observed with MOCVD susceptor materials

- 4H DSP SiC measured during MOCVD growth

- Direct SiC temperature now available during MBE and MOCVD growth

- RT–1300°C

- 2” and 3” 4H DSP SiC measured during MBE growth

- Substrate surface finishes and suggested holder examined for MBE growth

Introduction & Motivation

Many of today’s high-power radio-frequency electronic devices and high-output HBLED’s rely on SiC substrates for active layer deposition of GaN and SiC materials because of its high thermal conductivity and its close lattice match to GaN. The quality of such devices depends directly on the film temperature, but accurate film-temperature measurement is not possible using current optical monitoring techniques: SiC is transparent in the range of wavelengths current techniques monitor, so they are only measuring the temperature of the heater or holding mechanism. Now, however, using new special signal conditioning and processing, kSA BandiT can monitor the film temperature directly. BandiT’s accuracy has been verified on Aixtron MOCVD systems as well as a GEN20 MBE.

Measuring SiC Substrate Temperature with kSA BandiT

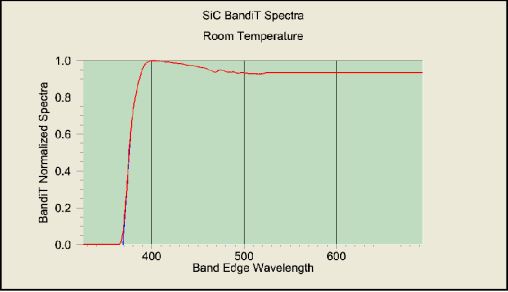

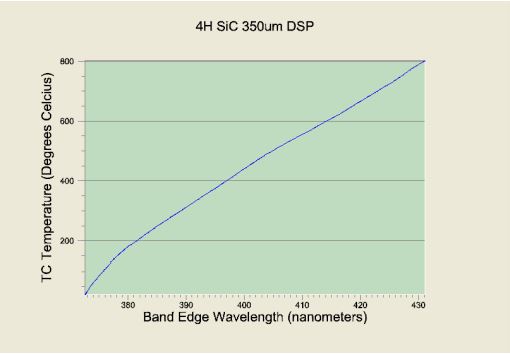

kSA BandiT band-edge detection on wide band gap semiconductors (SiC, GaN, SrTiO3) requires different spectra processing than standard gap semiconductors (GaAs, InP, Si). This is because the absorption edge is typically in the range of 350–600nm, depending on temperature. The sensitivity of solid-state spectrometers in this blue range is lower and the kSA BandiT broadband light source generates less light in this range. To compensate for this, kSA BandiT uses a reference spectra of the substrate, typically taken at room temperature. That spectra is then normalized and divided into the normalized substrate spectra at all temperatures. In this way, the signal strength is maximized and suitable for band edge thermometry with kSA BandiT.

Figures 2 and 3 show the SiC processed spectra at room temperature and also at 1050ºC in a commercial MOCVD reactor. As shown, BandiT yields a very clean band edge, which is required for accurate temperature measurement of SiC from RT-1050ºC and higher.

While a strong band edge can be seen, the ultimate signal strength and temperature resolution achieved is heavily dependent upon the substrate holder used, surface finish, and any back-coating of the SiC substrate itself.

Since SiC is semitransparent and typically double-side polished, maximizing the band edge signal for temperature monitoring is critical. Recent work at k-Space and its collaboration partners now allow for holder and operational recommendations for monitoring SiC substrate temperature in most MOCVD and MBE systems.

Multiwafer MOCVD Results With 4H SiC Substrates

Most commercial MOCVD systems use a wafer holder or susceptor that is made of graphite or SiC coated graphite material. These SiC substrates are placed into pockets within these holders that act to both hold the substrate in place during rotation and also to thermally conduct heat from the substrate heater to the substrate. kSA BandiT was installed onto a commercial MOCVD reactor in the configuration shown in Figure 1, utilizing a SiC coated graphite susceptor as mentioned above. By using the available rotational triggering signal available, kSA BandiT monitored temperature at any position within the platen radius during rotation on all wafers, along with providing spatially resolved data within each wafer.

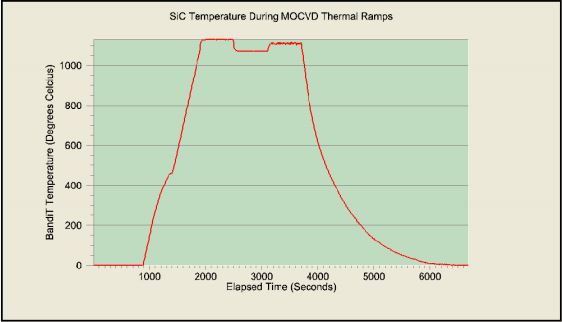

Due to the rough surface finish and susceptor material providing large amounts of diffusely reflected light, a very strong band edge was observed and used for temperature measurement. A thermal ramp from RT-1100°C is shown in Figure 4. This data was taken from a single wafer during multiwafer rotation. Additional data was taken to compare within-wafer temperature profiles towards matching heater zone power levels and ensuring wafer temperature uniformity.

Substrate Polishing & Coating Effects with MBE

The amount of diffusely reflected or transmitted light detected by BandiT in an off-angle configuration is significantly reduced for double-side polished (DSP) SiC substrates compared to the amount of light collected from a single-side polished (SSP) substrate. Because all known commercially available SiC substrates are DSP, we tested several such substrate configurations to better understand the constraints and solutions for commercial MBE and MOCVD systems. We have found that surface finishes among commercial SiC substrates can vary by vendor and by substrate size. However, most 2” SiC substrates with metal backcoat yield strong diffuse scattering signal for measuring SiC temperature without need for a backing plate or graphite holder. In addition, we found that bare SiC substrates with a PBN backing plate also provide a strong diffuse reflectance signal.

The PBN and most other ceramic holders (such as SiC coated graphite in most MOCVD systems) allows for light scattering and interaction with the SiC material to generate the appropriate absorption spectra for detection with kSA BandiT.

Figure 5 shows data from a metal back coated SiC substrate in a GEN20 MBE reactor. While the final SiC BandiT temperature was ~800°C, the GEN 20 substrate thermocouple read ~1050°C. This difference is expected because SiC at that temperature is transparent to the heater’s infrared radiation and hence is difficult to heat, requiring significant heater power.

Measure SiC Substrate Temperature Directly

By taking into account non-linear spectrometer sensitivity and lamp output via a reference spectra divide, we are able to fit the optical absorption edge for SiC substrates during MBE and MOCVD growth. This abortion edge is used to accurately determine wafer level temperature from RT-1100°C (depending upon SiC polytype). The amount of diffusely reflected signal for analysis strongly depends on the polishing quality of the DSP substrates, and the substrate holder/susceptor material and finish. While there are some limitations with MBE growth on SiC related to sample holder and surface finishes, we have observed no such limitations with commercial MOCVD systems that utilize SiC-coated graphite susceptor materials. We are not aware of any other technique that can provide true SiC wafer temperature. Please contact k-Space Associates for more details.