Product Specifications : kSA MOS ThermalScan

Version: 1.0

- kSA MOS ThermalScan

- Product Description

- Equipment Configuration

- Specifications and Models

- Options

- kSA MOS ThermalScan Computer Hardware and Software

- Installation and Training

- Distributors

kSA MOS ThermalScan

Full Temperature-Dependent Mapping of Curvature, Film Stress, Tilt, and Bow Height

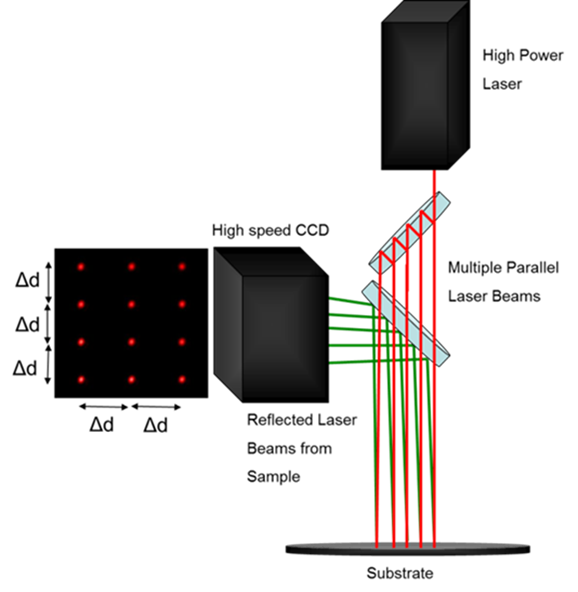

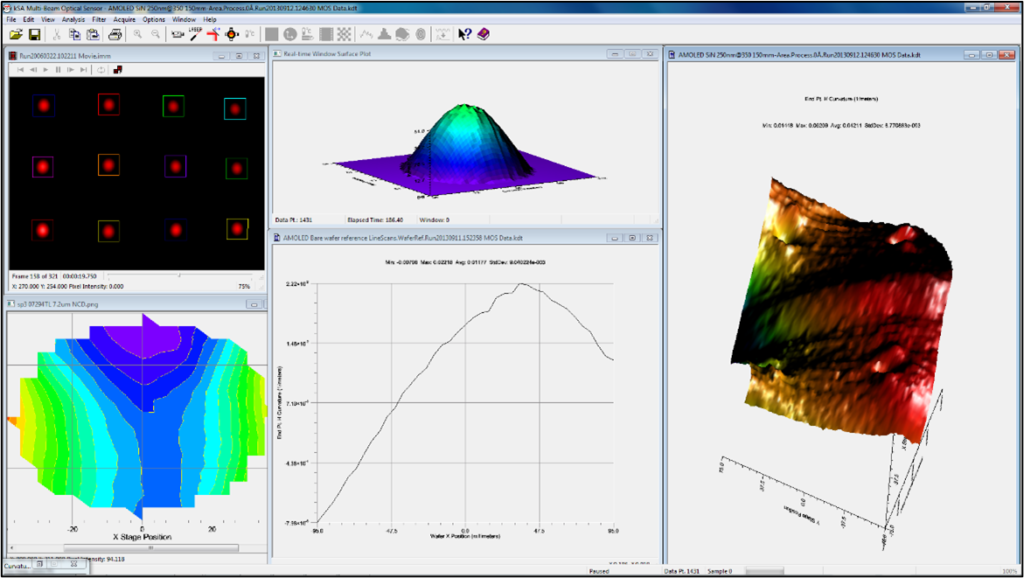

The kSA MOS ThermalScan is a flexible, high-resolution scanning metrology instrument that measures curvature, film stress, bow, and tilt as a function of sample temperature. Based on proven and patented kSA MOS technology, the kSA MOS ThermalScan uses a laser array to map the two-dimensional curvature, wafer bow, and stress of semiconductor wafers, optical mirrors, lenses – practically any polished surface.

| Measures: |

|---|

| Curvature |

| Bow height |

| Thin film stress |

| Tilt |

| Absolute reflectance |

| Film thickness and spectral reflectance (Optional) |

| Materials: |

|---|

| Wafers |

| Optical Mirrors |

| Lenses |

| Hard Coatings |

| Polished Surfaces |

Product Description

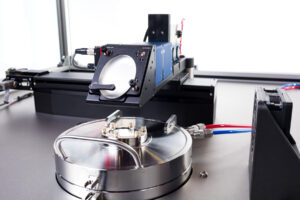

Leveraging k-Space’s expertise in integrating critical thin film metrology equipment, the kSA MOS ThermalScan system utilizes the patented MOS (Multi-beam Optical Sensor) measurement technology to provide unparalleled curvature, stress, and bow height accuracy, resolution, and repeatability. The system is configured with a high-performance vacuum process chamber utilizing advanced rapid thermal annealing heaters and quartz sample holder to maintain wafer temperature stability and uniformity across the entire rated temperature range from room temperature to 1000°C. If you need to know changes with temperature below this, an option is available to measure temperatures down to -30°C.

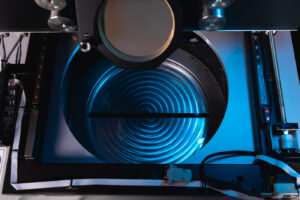

Measurements can be made during introduction of forming or other gas, with two gas introduction lines included in the standard product configuration. Gas control is accomplished with manual set point flow meters, digital readout, and software-controlled solenoid On/Off valves. Patented multiple-spot laser array and auto-intensity feedback control ensures kSA MOS technology is compatible with substrates having a wide variation in surface reflectivity.

Patented kSA MOS 2D laser spot array used for curvature/stress measurements.

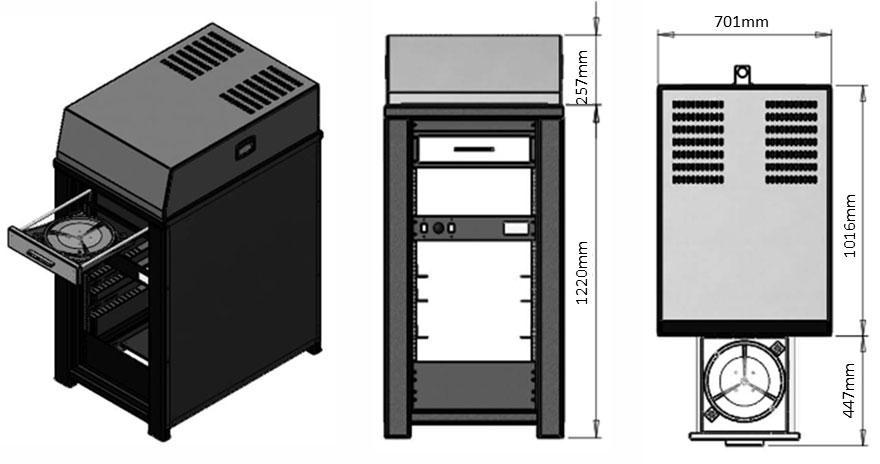

Equipment Configuration

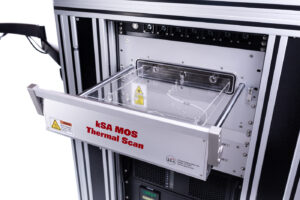

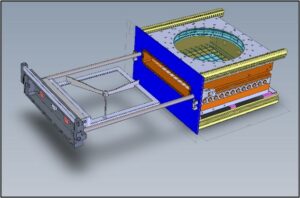

The vacuum heating chamber utilizes patented rapid thermal annealing technology in a completely integrated system with circulated water-cooled chamber, vacuum compatible sample compartment with sample locating features, and integrated thermocouple. The heating is performed with a high uniformity crossed quartz halogen lamp array for maximum temperature uniformity and stability. The system is capable of heating substrates to 1000°C under vacuum or process gas environments. See Model Table for more details.

General System Specifications:

- Maximum substrate size: Holds up to 300mm diameter wafer with provisions for 100mm,

150mm, 200mm and 300mm samples.* 50mm wafers, 75mm wafers, and odd shaped samples can be measured with the use of a 100mm graphite susceptor (quoted separately). See Model Table for more details.

- Substrate heater temperature range: RT up to 1000°C

- Process gas introduction lines with manual flow adjust, digital readout and software-controlled

solenoid on/off valves. Compatible with forming gas, oxide, or inert gas use during heating.

*300mm wafers should only be scanned over the central 200mm to maintain the accuracy specified in this document.

Vacuum Chamber:

- Water-cooled rapid thermal annealing chamber with O-ring sealed front loading chamber, sample holder,

and full upper quartz viewport to facilitate measurement.

Frame Assembly:

- A robust steel frame houses the entire chamber, control electronics, and metrology system.

- The frame has retractable castors so that the system may rest on vibration isolation pads.

Substrate Heater and Temperature Control:

- Substrates are free standing with an integrated thermocouple.

- Heater is a patented crossed-array quartz halogen lamp design, with bottom heating elements for maximum substrate temperature uniformity and stability.

- Substrate temperature is controlled via a programmable closed-loop temperature control unit and power supply.

- Temperature uniformity: better than ± 2°C across central 80% of sample when measured with sample at stable temperature.

- Temperature measurement accuracy is dictated by standard thermocouple accuracy.

Vacuum/Pumping:

- Vacuum gauging includes one gauge with digital readout and process pressure setpoint relay for safety interlock control.

- Diaphragm backing pump with all pump controllers is required and may be supplied by the customer or by k-Space. System includes related manual isolation and control valves that can be fully integrated to achieve 750 mTorr (~1 mbar) base pressure or better.

Specifications and Models

Standard Specifications for All Models

| Parameter | All Models |

|---|---|

| Measurement Range* | 1MPa – 7.8GPa |

| Temperature Range | See Model Table Below |

| Temperature Ramp** | 6 - 30°C /minute (0.1-0.5°C /sec) |

| Temperature Uniformity | +/- 1% on 300mm wafers up to 650°C |

| Repeatability* | 0.32 MPa2 |

| Accuracy* | < 1% or 0.32 MPa (whichever is larger) |

| Minimum Radius | 2.0 m (customizable to 1.0 m) |

| Maximum Radius*** | 25,000 m |

| Curvature Repeatability**** | 4e-5 (1/m) |

| Bow Height Repeatability**** | 1µm for 10 line scans |

| Wafer Sizes (mm) | 100, 150, 200, and 300 mm (custom sizes available with separately quoted graphite holder) |

| Minimum Scan Step | 0.001 mm |

| 3D Analysis Software | Standard |

* Assumes 725 µm Si substrate thickness, 180 GPA biaxial modulus for Si Substrate, and 1µm fil thickness. 300 mm wafers should only be scanned over the central 200mm to maintain the accuracy specified in this document.

**Cooling rate will be slower and is dependent on process conditions of chamber pressure and gas flow rate.

***Based on 1-sigma curvature repeatability of line scans and area scans. System dependent. Please ask your k-Space representative for data for your scenario.

**** Measured at room temperature

Models and Features

| Feature | Model TS100 | Model TS300-MT | Model TS300-HT |

|---|---|---|---|

| Scan/Wafer Size | Up to 100 mm | Up to 300 mm | Up to 300 mm |

| Maximum Temperature | Up to 1000°C | Up to 600°C | Up to 1000°C |

| With Cooling Option | Down to -30°C | Down to -30°C | Down to -30°C |

| Scan Type | Center Point Only | Area | Line Scan Only |

| Second Lid for Scan Type Option | - | - | Add a second lid for Area Scan to 600°C; Line Scan to 1000°C |

Options

There are several options available to measure your wafer under the conditions that you need. Please ask your k-Space representative for more details on these options.

- Cooling to -30°C

With the cooling option, cooling is performed through a Brooks Polycold gas chiller to measure the sample at below zero conditions. Without the cooling option, the standard minimum temperature is room temperature.

- Higher Curvature Measurement

For high curvature samples, we offer an upgrade that increases the size of the optics to allow measurement of up to 2mm bow height on 300mm samples.* The size of the optics housing and the overall width of the tool also increase by a small amount. The minimum radius and maximum bow height are sample diameter dependent. Contact your k-Space representative for more details.

- Different Sample Sizes

For non-standard samples, we can provide a graphite holder option. Contact your k-Space representative for more details.

- Area and Linear Scans

For the Model TS300-HT, a second lid can be added to provide area scan capability up to 600°C.

- Other

Other customizations are available to meet your needs. Ask your k-Space representative about how we can design a customized tool for what you need to measure.

*300 mm wafers should only be scanned over the central 200mm to obtain the accuracy specified in this document.

kSA MOS ThermalScan Computer Hardware and Software

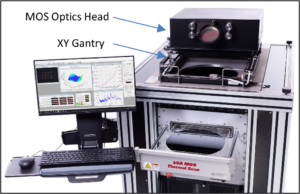

- Complete kSA Multi-beam Optical Sensor (MOS) ThermalScan System for measuring wafer curvature, wafer bow, and thin-film stress.

- Configurable scan resolution parameters.

- Integrated scanning stage to allow for line scans and full 2D area scans of up to 300mm samples through optical viewport at stabilized temperatures, and center point during ramping of temperature. Model dependent.

- Patented, Automated Mirror Tracking with Servo Control and auto-intensity laser control ensures kSA MOS signal continuity during thermal expansion effects, surface reflectivity changes, and large variation in curvature/tilt during thermal cycling.

- Thirty (30) 2-D curvature/stress measurements per second (maximum rate) when acquiring data at center point of wafer. Slower data rates are fully programmable.

- Thermal scan software to provide fully automated multi-segment ramp/soak recipe control for annealing studies. Curvature and stress can be monitored and plotted as a function of temperature and time. Up to 100 cycles.

- Complete data storage, including full digital movies of the laser array that can be re-analyzed or incorporated into presentations.

- Complete publication quality graphics and color display.

- Export of all data to Windows Excel format or ascii text file.

- Offline analysis available with supplied Analysis Only software license.

Computer Specifications (Minimum):

- Model: 4U Rack Mount Server Case

- Operating System: Windows 10

- Optical Drive: None (optional)

- Processor: Intel i5 Quad Core Series Processor

- Graphics: Sapphire Radeon HD 6450 1GB DDR3

- Hard Drive: 1TB 7200rpm 6.0Gb/s

- Memory: 8GB (2×4 GB) DDR3 1600 SDRAM

- 22” LCD flat panel display on frame-mounted arm with keyboard and mouse platform

Warranty:

All kSA systems and integrated components are warranted against defective materials and workmanship for a period of ONE YEAR from the date of delivery to the original purchaser.

Installation and Training

Installation and Training

A minimum of five days of installation is required. Additional support for tool training suggested. Any customer defined tool acceptance criteria will need to be approved by k-Space prior to tool purchase and additional service for acceptance testing is required.

Customer Facility Requirements

- Cooling Water: Approximately 15 L/min, pressure differential 2-3 bar, stable incoming temperature 15°C-18°C, Two ½” Swagelock fittings provided for both the inlet and outlet connections

- Vacuum Connection: KF25 flange provided, requires 2.8 m3/h

- Exhaust Connection: KF40 flange provided, requires 60 m3/h

- Process Gas connections: Two ¼” Swagelok connections provided for room temperature Nitrogen or Argon process gas connections

- Power: RTP furnace power supply requires 3 x 230 V (3 Phases with neutral) in star connection (460V phase to phase). As part of the tool price k-Space provides 240V 1-phase UPS for backup of critical components such as CPU, gantry stage power and optics head power. The RTP furnace is NOT typically on backup power. A 5-wire, 3- phase UPS may be used to provide backup power to entire system (including RTP furnace) if supplied by the customer.

- All safety considerations will be provided by k-Space in the kSA MOS Thermal Scan User Manual.

- k-Space uses all CE marked components.

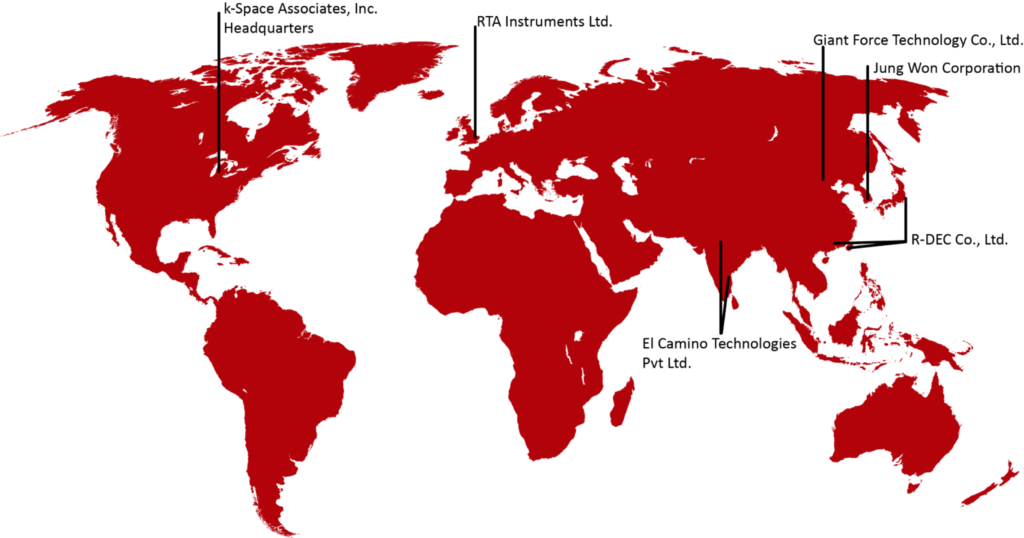

Distributors

k-Space has an expansive network of distributors to best serve our worldwide customer base.

HEADQUARTERS

k-Space Associates, Inc.

Michigan, USA

www.k-space.com

[email protected]

DISTRIBUTION PARTNERS

RTA Instruments Ltd.

Europe

www.rta-instruments.com

[email protected]

El Camino Technologies Pvt Ltd.

India

www.elcamino.in

[email protected]

Giant Force Technology Co., Ltd.

China

www.giantforce.cn

[email protected]

Jung Won Corporation

South Korea

www.jwc.co.kr

[email protected]

R-DEC Co.,Ltd.

Japan

Hong Kong

Taiwan

www.rdec.co.jp

[email protected]