At k-Space, we offer custom framing solutions to ensure our metrology tools will all run perfectly in your work environment, right from the start.

There are now no barriers to the measurements you can take to meet manufacturing quality, throughput, and safety requirements.

k-Space industrial metrology tools measure for surface quality, edge grind, glass breakage, spectral reflectance, film thickness, and more. Not sure if they will work in your production environment? Our custom frame designs account for layout, conveyor type, throughput, and other factory floor concerns. You can be assured our non-destructive optical metrology solutions will fully resolve your unique measurement needs.

Check out some custom design samples below. Then contact our Sales Engineering team to discuss your unique measurement challenges.

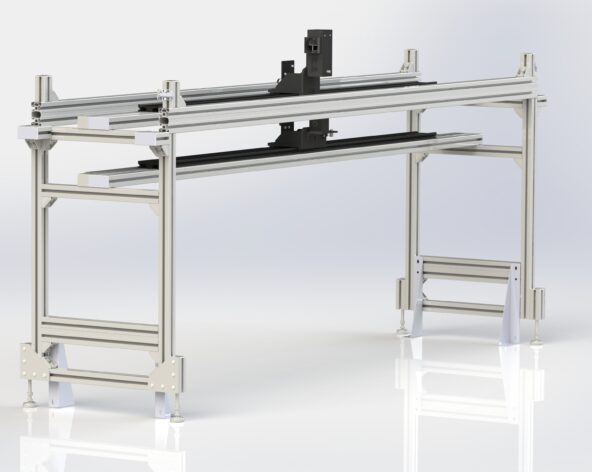

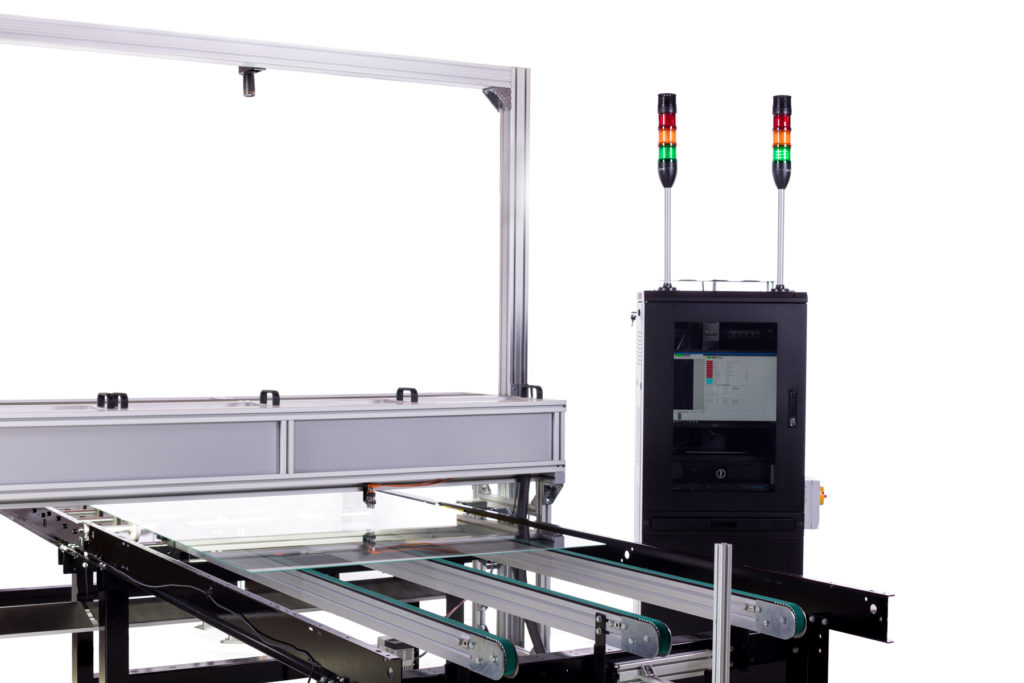

Custom Frame Example 1

Our Panel Edge Profile Metrology system uses a straightforward frame with crossbeam and leg supports to mount displacement sensors in-line, over-the-conveyor, to inspect glass panel edges.

This modest, yet versatile design is for stationary sensors, which can be repositioned by loosening a few screws and sliding the brackets along the extrusion.

This ultra-wide frame is used when panels are transported side-by-side.

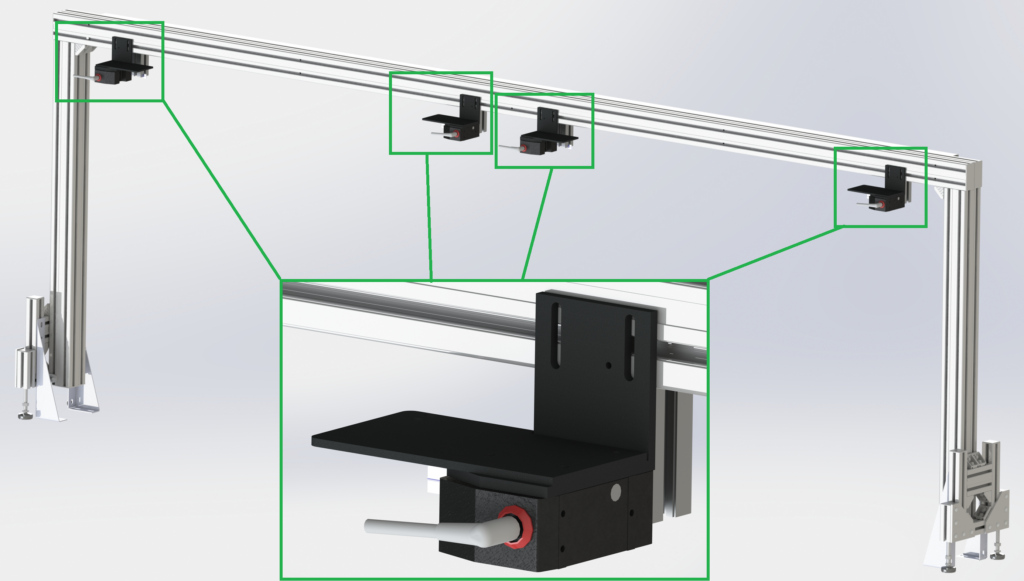

Custom Frame Example 2

Our Inline Sheet Resistance system incorporates a frame design for when sensors are needed both above and below the panel.

In this case, the sheet resistance sensors are mounted on rails and carriers to allow for easy repositioning of the sensors to inspect positions along the panel.

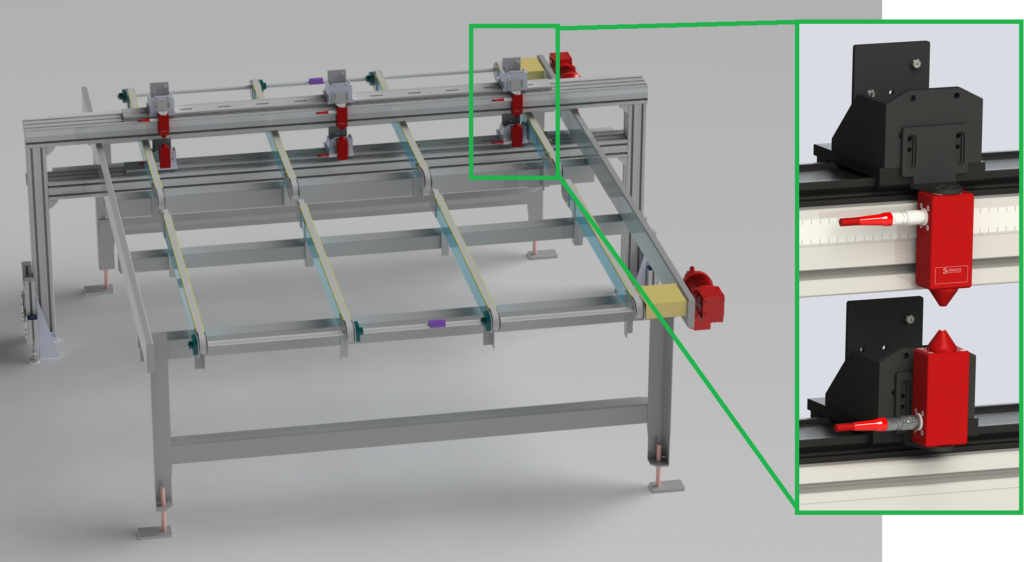

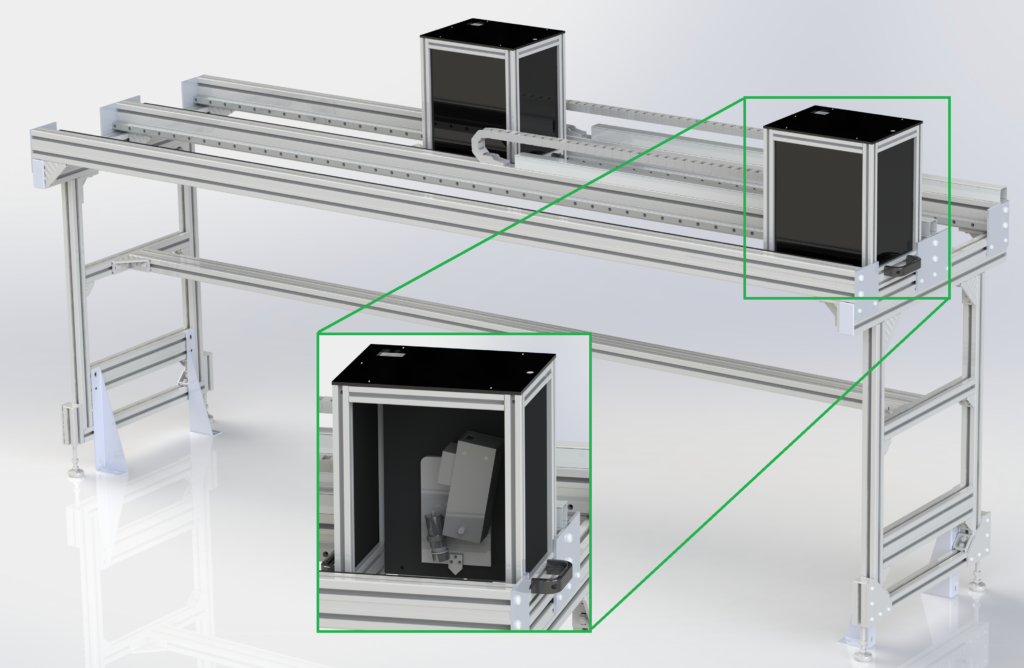

Custom Frame Example 3

This custom industrial frame design includes coverings for sensitive optical sensors. The casing prevents stray light from generating noisy data. Plus, the solid block and rail design allows for offline measurements.

This frame design is typically used for spectral reflectance and reflectance & transmission measurements. Moving the optical focus off a panel onto a coupon is made easy with this system.

What’s Your Measurement Challenge?

k-Space prides itself on quality metrology tools that seamlessly integrate into any factory floor setting. Contact our Sales Engineering team today to discuss your measurement challenges.