At k-Space, we put light to work, building the world’s leading thin-film and industrial metrology tools. We also put our bank of 3D printers to work, crafting custom metrology parts and accessories.

The 3D printing approach is great for prototyping and initial testing of new designs. We then will typically have the part made from aluminum or stainless steel for the final version.

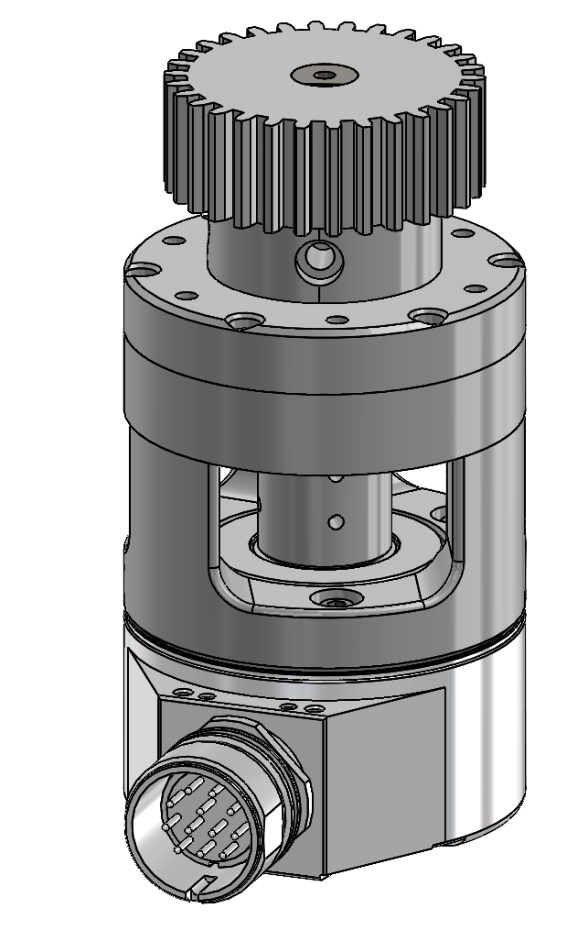

An example of our 3D printing is this planetary gearbox, also called a gear reducer.

We design the gear reducer, like all such parts, to the customer’s unique needs, then ‘print’ it in our dedicated 3D printer room. This particular gear reducer is a kSA 400 accessory. It’s for when the customer is using RMAT and doesn’t have a 1:1 gear ratio. In this case we don’t need to make the final part out of metal, as the 3D printed gear is plenty strong and has minimal wear over time.

The gear reducer shown here is just one example of the items we print to enhance our metrology tools.

Combining our metrology expertise and 3D printing abilities, we are able to design and build the exact metrology tool each customer needs, at a fair price and faster than via traditional means.

To get a closer look at our 3D print facility, and an inside look at the k-Space engineering and production facilities, check out our drone flythrough.