The kSA Glass Breakage & Defect Detection tool is a vision-based metrology system that determines Go/No-Go (Pass/Fail) conditions for every glass lite and panel it inspects inline during processing. It identifies cracks, chips, scratches, digs, pinholes, and numerous other factors for both clear and transparent glass as well as opaque glass.

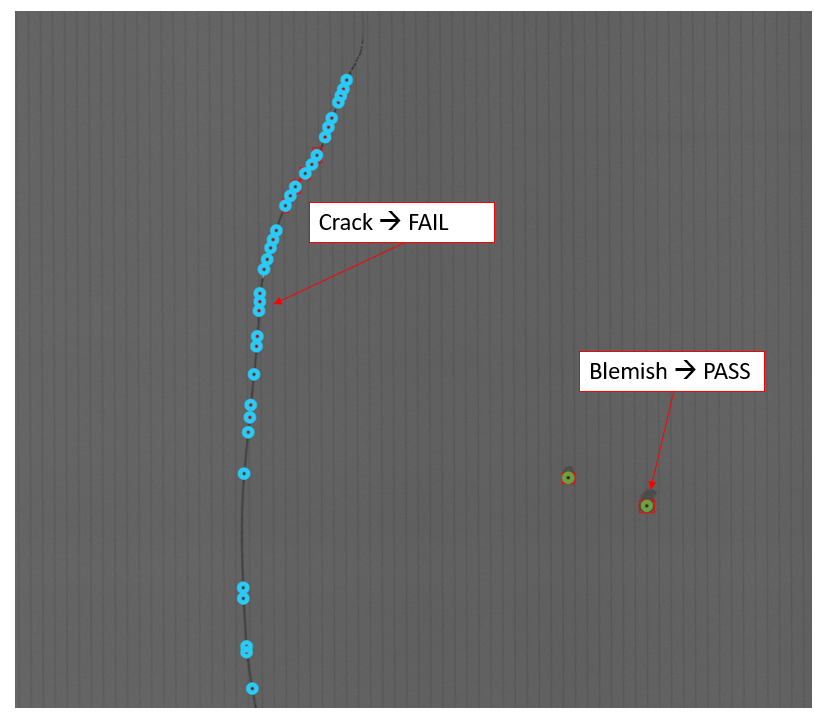

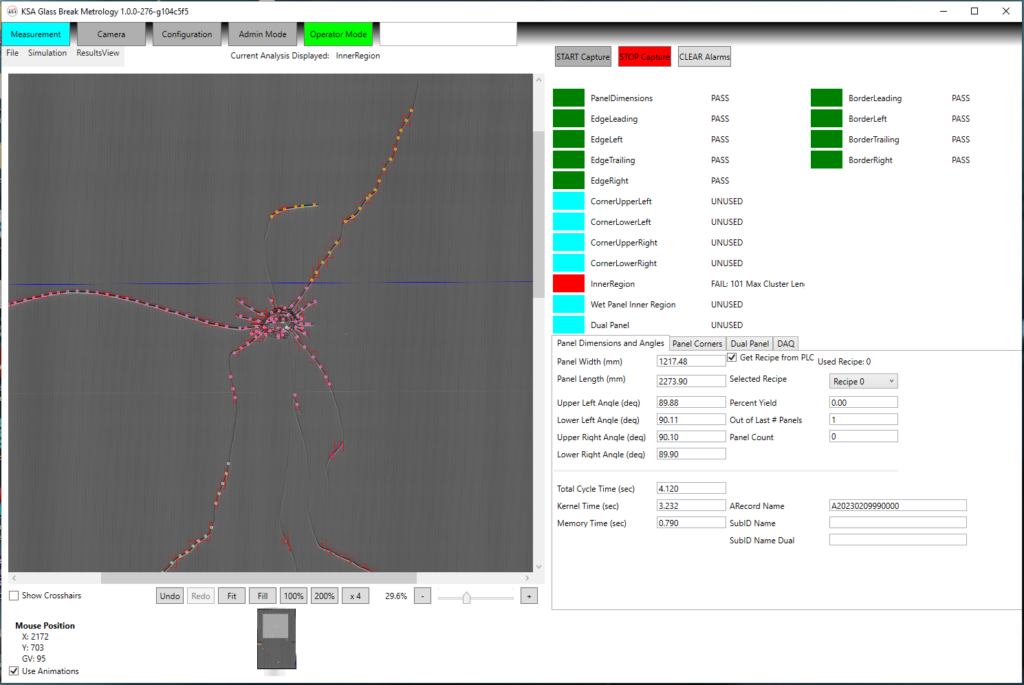

An innovative new feature of this tool is how it determines what is a crack versus what is merely a blemish.

To achieve this, the software algorithm uses a cluster analysis that strings found defects together to represent cracks. This allows the system to correctly identify cracks as distinct from blemishes. The images below make this clear.

The Glass Breakage & Defect Detection tool can be customized to the manufacturer’s unique product dimensions, standards, manufacturing processes, and production volumes.

Email us to find out more.

The video below explains how the glass defect detection tool can reduce downtime, scrap costs and returns, and make for a safer work environment.

Photo eyes detect the leading and trailing edges of the panels and trigger the system to start and stop data collection.

Factory integration capabilities enable users to incorporate the tool into their existing systems, including factory alarms, PLC, email alerts, QC, and more.